Custom made for you

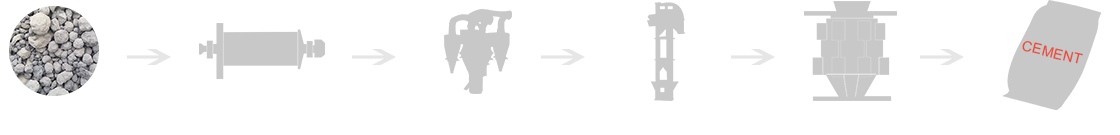

The whole system of cement grinding plant mainly includes cement grinding, cement homogenization and batching, cement packaging and bulk loading. And the system is composed of cement mill, OSEPA high-efficiency separator, elevator, packing machine and so on. In order to meet the customers' requirements on different granularity of auxiliary materials, it can be equipped with high-efficiency hammer crusher for optimal combination and classification.

Cement Ball Mill

Cement Ball Mill

OSEPA High-efficiency Separator

OSEPA High-efficiency Separator

Elevator

Elevator

Packing Machine

Packing Machine

Various materials are quantitatively given in the cement batching process according to the set ratio. After the materials are discharged proportionally by the feeding metering equipment, they are sent to the ball mill by belt conveyor.

The ground material is transported up by the bucket elevator to the separator. After separating, the materials that do not meet the particle size requirements are transported from the air chute to the ball mill for regrinding. The dust of the ball mill is transported to the dust collector by the pipeline. The qualified materials sorted by the separator and the dust deposited by the dust collector are transported together by the air chute to the bucket elevator, and then lifted to the stock bin.

The materials in the stock bin are conveyed from the air chute to the bucket elevator, and then from the bucket elevator up to the vibrating screen to screen out the impurities in the materials. The filtered materials enter the silos, then are sent to the packing machine by the rigid impeller feeder, and finally the cement packed into bags is transported to the warehouse by the flat conveyor.

The CHAENG cement grinding station overcomes the traditional equipment’s shortcoming that the clinker grinding cost is too high. The system configuration is reasonable, the production efficiency is high, the output is large.

The cement grinding station is equipped with a modern electronic control operating system. It has a high degree of automation and simple operation, requiring no manual operation except for the switch machine and routine maintenance.

CHAENG can provide customers with: ① complete equipment and accessories for cement grinding station; ② EPC services: complete solutions including design, research and development, manufacturing, transportation, installation, commissioning, training, and after-sales.

| Capacity | Feeder Machine | Cement Mill | O-Sepa Separator | Bucket Elevator | Packing Machine |

| 15t/h | DEL0620 | φ2.2x11m | N500 | NE100x25m | BGYJ-2 |

| 50t/h | ZSW100 | φ3.2×13m | N1500 | NE200x31m | BYHW-8 |

CHAENG can provide the complete solutions of 15-100t/h cement grinding station for you. Please send email to vip@chaeng.co for the quotation.

Customer feedback:

Mexican Client

Mexican Client

Tanzanian Client

Tanzanian Client

Chile Client

Chile Client

Technical personnel are designing the optimal cement grinding station program for you.

The cement grinding station equipment are assembled here.

The cement grinding station equipment are processed and shaped here.

Storage the grinding plant equipment, which will be sent to your country soon.

Here are all your parts, we will configure them promptly.

Tel.:86-371-55019878

WhatsApp:+8613071023171

skype:GreatWall1958

Office Add: Mengzhuang Town, Huixian City, Henan Province, China

E-mail: vip@chaeng.co