Vertical roller mill is mainly used for grinding raw meal, clinker, GGBFS(Ground Granulated Blast Furnace Slag), iron ore, limestone, coal powder, coke powder, coal gangue, fly ash, volcanic ash, gypsum, calcite, pyrophyllite, quartz, clay, sandstone, bauxite and other processing industry related to metal and non-metal mine

Product Introduction

The vertical roller mill has been widely used and promoted in the electric power, metallurgy, chemical industry, non-metal industry because the overall efficiency attributed to energy-saving and low consumption is becoming more and more evident in the cement industry.

GRM series vertical roller mill is developed with the features of high efficiency, energy-saving and environmental protection which is achieved after exchanging ideas with senior experts from home and abroad and making improvements based on same sector experience in the past years.

GRMC series typically designed to process materials in medium hardness, like soft coal or bituminous coal.

GRMK series is mainly used to grind cement clinker into fine powder during cement production,This cement mill widely used in the grinding of raw cement, slag, cement clinker, raw coal and other raw materials.

GRMSseries GGBS vertical roller mill is the equipment to grind Ground Granulated Blast furnace Slag (GGBFS),Nickel Slag, Manganese slag and other ore slag into small particles.

Product Application

GGBS production line, coal powder production line and other processing industry related to metal and non-metal mine. grinding raw meal, clinker, Ground Granulated Blast Furnace Slag, iron ore, limestone, coal powder, coke powder, coal gangue, fly ash, volcanic ash, gypsum, calcite, pyrophyllite, quartz, clay, sandstone, bauxite and other processing industry related to metal and non-metal mine.

Characteristic Features

1) High grinding efficiency and lower energy consumption

2) Lower metal consumption per unit of product

3) Grinding on the material layer bed, minimal sound emission

4) Operation under negative pressure and minimal dust pollution

5) Simple process flow with the combination of grinding, drying and classifying in a single unit

6) Less land occupation, tight layout, light weight, lower civil works cost

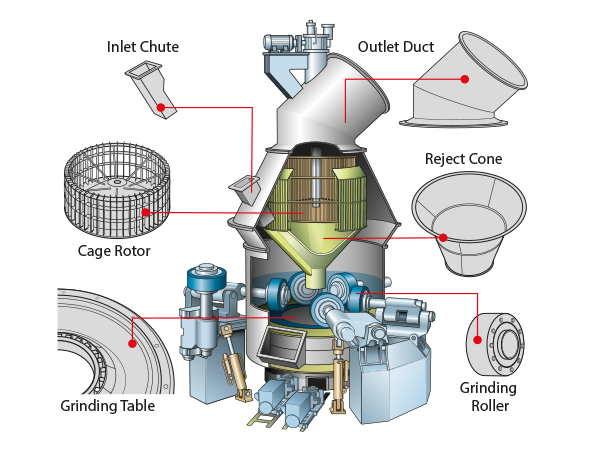

Structure of vertical roller mill

1) The combined classifier improves the powder selection efficiency.

2) It is not necessary to distribute material on the grinding plate before start-up. The roller can be lifted up and down automatically and start without load.

3) It is well sealed by welded arc plate and structure is simple and reliable

4) With the help of roller turning device, it is easily to turn the roller out for maintenance.

5) Both sides of roller sleeve can be used so that the service life of refractory material is extended.

6) Grinding roller limit device can ensure a certain space between roller and grinding table, which avoids the direct friction and collision between roller and grinding table and enhances safety

7) The grinding roller is driven by spinning grinding table. Pressure filling and adjustment and roller lifting can be remotely controlled without operator on-site.

8) The roller bearing is circularly lubricated by thin oil to enable it to work under low temperature and clean grease so that the service life is extended

you can see more by Vertical Roller mill project Video

Great Wall technical center can help our client to finish feasibility study, environment impact assessment and safety assessment and also provides turnkey service with high efficiency.

Great Wall has its own various processing equipment and takes strict control measures on product quality, which results in fast delivery within a short time. Besides, Great Wall can guarantee completion and operation as scheduled with its strong service team for installation and after–sales service.