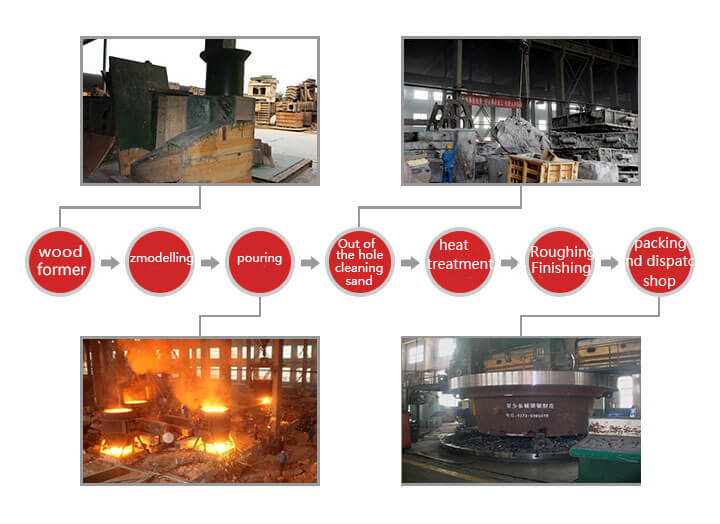

The grinding table is one of the key parts of vertical roller mill It includes drag rings, segments (lining plate) and bases The optimization and improvement are made by us on the traditional grinding table casting technology, that the most advanced sodium silicate-bonded sand molding technology, to overcome the deficiencies in structure and make the grinding base bear force equivalently All of these avoid the problem of material’s washout on the not wear-resisting surface

The grinding tables produced by us have the features of high hardness, good anti-cracking.

We carry out the grinding table dressing and finishing machining by the equipment of arc air gouging and shot-blasting, which can guarantee the quality of the steel castings.

Before delivery, all the grinding tables shall have NDT inspection several times as per perfect inspection flow. Any of defective products is forbidden to leave the factory.

see more details >>

By years of efforts and development, our customer has been spread all over China, America, Germany and other european countries. The good service and product quality advantage makes Great Wall Machinery a strategic partner with the world well-known large machinery manufacturer. We become the best supplier of these companies.

The grinding table is applied to vertical mill GRMK46.41 with annual capacity of 0.9 million tons cement in Henan Yuhui Huanghe Construction Materials Co., Ltd. At present, the mill runs in good condition and won reputations in our China customers.