Industry Reports

High quality steel castings-vertical mill wheel hub manufacturers

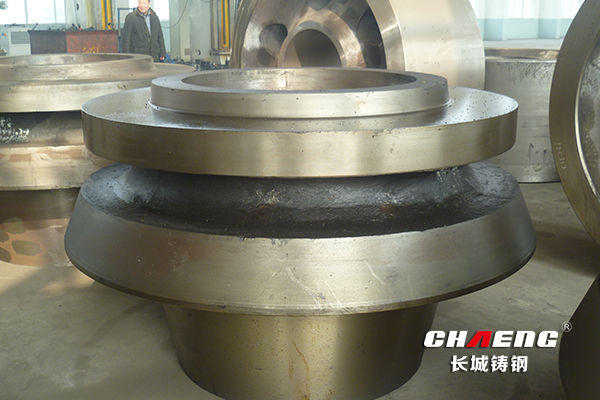

The wheel hub is the core component of the vertical mill grinding roller assembly. The roller sleeve is fixed on the wheel hub, and the wheel hub is mounted on the roller shaft to form a grinding roller assembly. Generally, a tapered structure is adopted between the roller sleeve and the hub, which ensures the convenience of later inspection and disassembly.

According to the drawings provided by customers, Great Wall Cast Steel can carry out custom processing of various steel castings with a weight of more than 5 tons.

Product advantages

1. Select the best alloy steel material, the comprehensive mechanical performance is better, and the service life is longer;

2. The production of large-scale steel castings is rich in experience, and it can design matching casting technology according to the structure and technical standards of steel castings;

3. With advanced flaw detection equipment, it can ensure the precise control of the inner quality of the vertical mill wheel hub and prevent any defective products from leaving the factory;

4. Strong strength, short casting cycle, steel casting blank production cycle is between 25-45 days, depending on the casting process and product technical requirements

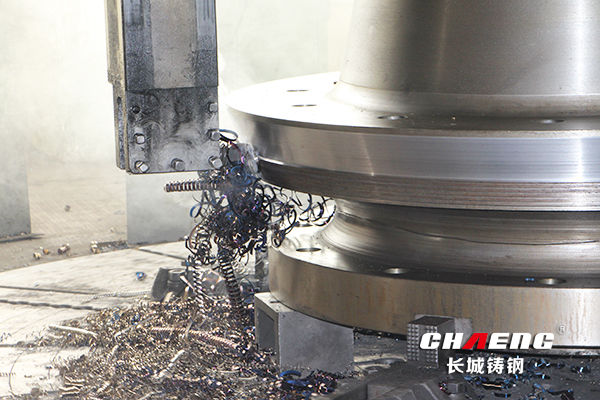

Process flow

According to customer requirements, Great Wall Cast Steel selects the appropriate wood mold for modeling design, and adopts Huazhu CAE simulation before pouring, strictly in accordance with wood mold-shape-smelting pouring-insulation-out-pit clearing-heat treatment-roughing-adding-packaging The process of delivery produces high quality wheels.