Industry Reports

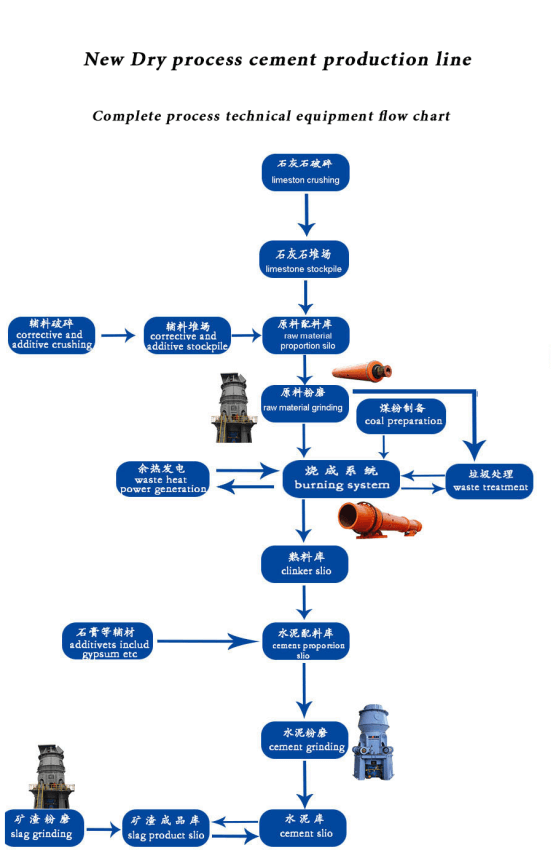

1000 TPD Energy Saving, Environmental Protection New Dry Process cement production line

Project Advantages

Powerful crushing,scientific stockpiling

The limestone crushing use single-section hammer crusher that feeding size is 800mm, production capacity is 180 t/h, and grinding by advanced vertical raw mill- GRMR22.31. Scientific material piling and taking technology, to achieve the initial raw material homogenization.

New vertical mill grinding process, Low energy consumption in grinding

The energy consumption in cement grinding process accounts for more than 60% of the whole production line, therefore, it has great significance in ensuring product quality and reducing energy consumption by using high efficiency and energy saving GRM series vertical roller mill to deal with raw material, coal, clinker.

preheating before calcination, High efficiency and energy saving

Raw materials are sent into φ3.2x50m rotary kiln to be calcined after preheating and precalcining in the cyclone preheater. That is conducive to improve the production efficiency of kiln system, shorten rotary kiln length, and reduce the heat consumption of clinker calcining.

Low Investment ,Environment Friendly

Vertical mill grinding system operate in negative pressure, low dust pollution; System equipment layout is compact, low area occupying, low investment in civil construction; Environmental protection in recycling kiln exhaust gas.