chaeng is a professional supplier of slag powder production line, can provide "turnkey" service from civil engineering to debugging and capacity and standard reaching to customers, let customers put into production of mineral powder with saving worry, saving effort and high-efficiency.

|

| Industrial waste slag grinding processing |

| Recycle waste material, reduce cost and increase income |

|

|

| Dear friend, |

| In order to solve the matter of high production cost of cement companies, and reduce the place for the large amounts industrial waste slag, Xinxiang Great Wall Machinery Co., Ltd has manufactured the upgrade GRM INDUSTRIAL WASTE SLAG PROCESSING SYSTEM. |

| It can REDUCE THE COST AND INCREASE THE PROFIT of steel industries, creating additional revenues. |

| The uses of industrial waste residue after grinding |

· For producing cement

· As the Cement and concrete admixture, improve the strength by 15-20%

· As the materials of Cast stone, microcrystalline glass, fertilizer, enamel, ceramic, etc |

| |

| The advantages of GRM system |

* Professional and reliable

* Economic and environmental

* Intelligent and safe |

| |

| Service you can get |

| We can provide the whole EPC services for production line: |

| ① raw material test |

② design of case |

③ equipment and manufacturing |

| ④ installation and debugging |

⑤ technical training |

⑥ reaching design output and standard |

|

| |

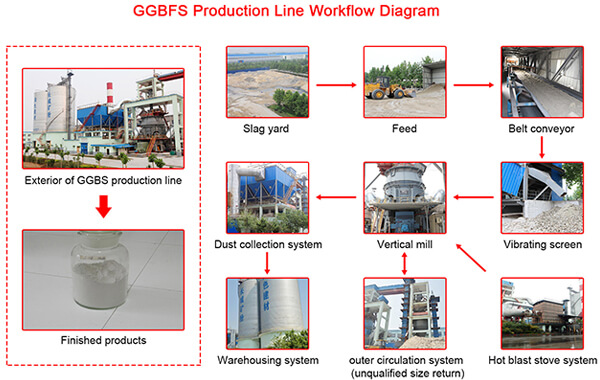

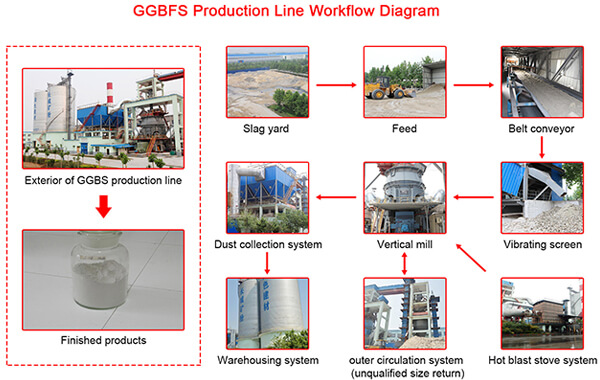

| The producing flow of GRM system |

|

| Cases |

| Country |

Company |

Project |

| Indonesia |

Indonesia Growth Steel Group |

300,000 t/a nickel slag grinding production line |

| China |

Baosteel Group Corporation |

1,500,000 t/a slag/steel slag grinding production line |

| China |

Aosen Steel Co.,Ltd |

600,000 t/a slag grinding production line |

| China |

Xuzhou South-East Steel Co.,Ltd |

300,000 t/a slag grinding production line |

|

|

|