Industry Reports

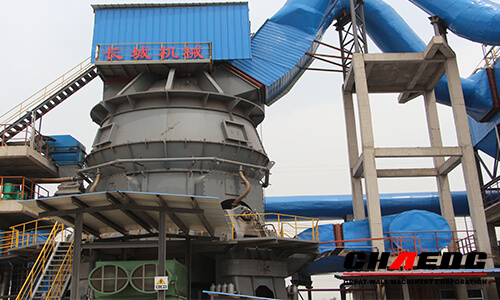

The main factors affecting the operating efficiency of raw material grinding system

The main factors affecting the operating efficiency of raw material grinding system in cement production line process.

The effects of the size and grade of limestone on the yield of the mill. Raw materials are mainly composed

of: limestone, sandstone (low silica sandstone), iron powder (iron ore), fly ash (slag), the proportion of limestone (the most important raw material ingredient) is 80%-83%.

1) When the limestone particle size is too large, the over-large particles will keep putting up instantly the grinding roller, as so to hamper a good grinding layer formation, increase the mill vibration value, and even cause vibration stop. When the limestone grain size is too large, the grindability is worse, so that mill rejects increase, the external circulation rises, and the output of the grinding mill will become low. If increasing the grinding pressure to to adapt to raw material, will increase the mill running current of the mill will increase; if mill vibration occurs during operation, the equipment will be damaged worse.

2) If limestone contains excessive mud, powder material is too much, cohesiveness is poor, the particle size distribution of raw materials will be unreasonable, resulting in unstable material layer and mill cycle increasing. That will cause collapse phenomenon, make the mill vibration value becomes large, and shut down the mill because of vibration, so as to affect the operation efficiency of grinding mill and decrease the output.

3) When the grade of limestone is bad, it can be distinguished from the surface view. The black stone in limestone is easy to change. When the poor grade limestone enters the mill, the amount of slag will be increased, and the outer circulation will be increased, so that the output of the mill will decrease.