Industry Reports

slag grinding plant/slag grinding line/slag prodution line

Capacity : 20-150 million t/a

Main engine : GRMS slag vertical mill

Grinding Material : slag, waster slag, Blast furnace slag

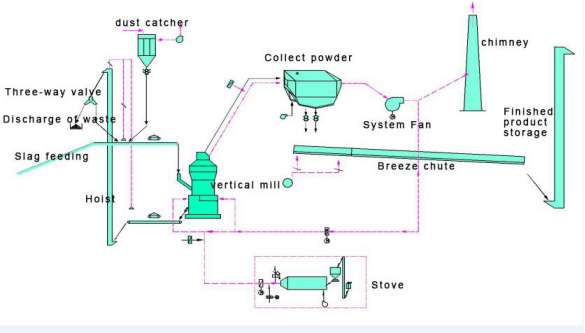

Match Equipment type: belt feeder + vibrating screen + slag vertical mill + hot stove + dust collector + finished product warehouse

Process introduction:

1、 why build slag production line

Over the past decade, it shows that the general trend of cement industry is with strength of cement rising and the clinker consumption decreasing in the Germany and Switzerland of the power cement world.In the future development of cement industry in Germany, it is still that the traditional Portland cement will be replaced by cement which is mixed with low clinker such like slag, fly ash, shale, ash, II sintering limestone, etc. And the slag will be used by more and more cement and concrete enterprises as a new type of admixture.

Slag powder is a superior performance of the concrete admixture, in the cement production of slag powder can increase the strength of cement 28D 15% - 20%, the allocation of 42.5 grade cement; in the production of concrete slag powder can be replaced by 10 ~ 50% of the cement, configuration C20 ~ C60 concrete, has become the international cement industry to reduce the cost of cement an important measure.

2.slag grinding plant Process flow

Piles of slag are taken and fed by the forklift truck, and conveyed by a belt conveyor. During the process of conveying, slag raw material will be iron-removing and screening through magnetic separator and vibrating screen, and then go to the weigher cabin, elevator and last to the vertical roller mill for grinding process. The ground granulated slag powder is drying by the hot air supplied by hot blast furnace, and with the help of hot air, the powder selecting is made in the separator. The qualified slag powder particles will be collected by bag filter, then conveyed and stored in the silos by the air slide and elevator.