Industry Reports

coal vertical grinding mill working principle

Chaeng coal grinding system specifications are divided into: GRMC17.21 coal vertical mill, GRMC19.21 coal mill, GRMC24.31 coal mill, its capacity design is divided into: 20t / h, 25t / h, 40t / h, in order to meet the market demand for a variety of coal-fired boiler applications, and the pulverized coal mill is the most leading international coal preparation equipment, access to domestic and foreign customers spoke highly of.

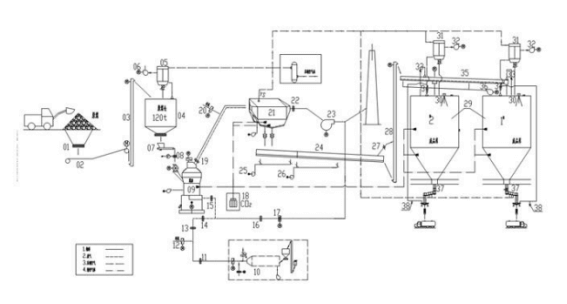

Firstly, what is a full set of coal mill equipment production process ?

Secondly, what is coal vertical mill work principle ?

Raw coal from the yard are conveyed through screen to belt conveyors. The raw coals after iron removal by electromagnetic separator are put into the warehouse for storage.

2. After grinding system has started, please turn on the rod valve in the bottom of raw coal storage, and start sealing measuring belt to coal mill, then raw coal will be dryed and ground in the vertical coal mill.

3. The mixture of hot air or waste gas of cement production line are sucked into Vertical Coal Mill, under blower’s function. After complete heat exchange with ground coal, the coal powder are brought to separator for separation. The unqualified coarse coal powder falls to the grinding table for regrinding. The qualified coal powder will be collected with the airflow into the anti-explosion impulsive dust collector, through the grid wheel are discharged into pulverized coal storage.

4. The debris of raw coal, such as coal gangue, metal block, etc. will be discharged through the wind ring, discharge hole.

Thirdly, what is the advantage of coal vertical grinding process?

1, set grinding, drying, powder selection, transportation in one, energy efficient.

2, the shape of the disc is conducive to the material after grinding to the edge of the disc was separated in time to reduce the grinding. High efficiency, low power consumption.

3, coal grinding mill can pull out the machine, maintenance and replacement of wearing parts is very convenient.

4, roller sleeve for the symmetrical tire shape structure, can flip the use of long life, low operating costs.

5, the separator for the efficient dynamic - static separator, high efficiency, low resistance.

6, with a limit device, in the disc when no material to prevent the roller and the disc in direct contact to avoid wear and severe vibration.