Industry Reports

Operational and Maintenance of Cement plant vertical roller mill

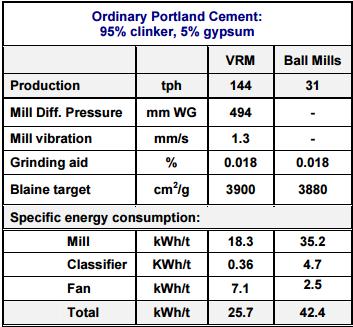

Cement Mill Operating Data:

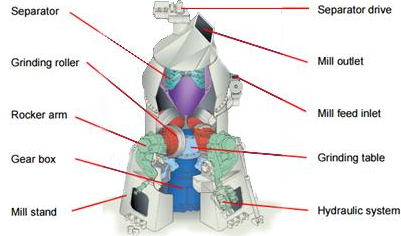

The VRM for cement grinding offers a significant advantage in power savings. Typically, the VRM uses 50% less power than a ball mill when grinding the same clinker to 3900 Blaine. VRMs are also much more adept at handling hot feed compared to ball mills. The simple and compact vertical mill layout is cost competitive to build and offers many options for layout, even in existing plants. Today significant operating experience has been accumulated with vertical mills ranging from plant design and layout to operation with multiple types of product. One of the main focus points regarding cement VRM operation in the USA has been product quality and the product compatibility with existing ball mill systems.

Maintenance of wear parts:

The vertical roller mill design allows the option of rotating the roller segments 180 degrees before replacing. They can also be hardfaced in place with a standard rewelding procedure. The table liners can also be replaced or hardfaced. As of this time both methods have been undertaken. After the mill was in operation for over 10,000 hours the roller and table wear rates have been measured 2 times, once through each method

Described above, roller segment rotation and rewelding of both the table and roller liners. The actual wear rate for both the roller and table liners before hardfacing was 0.30 g/T. The measured wear rate with hardfaced liners was 0.12 g/T. The 50% reduction in wear rate with hardfaced liners was expected as data from other vertical cement mills indicated such a savings could be expected. In either case the wear rate has exceeded expectations and operation has not been detrimentally effected by wear.

The VRM continuously demonstrates the ability to make product equal to or better than existing ball mills with the tendency towards the better. The VRM product meets all market requirements in terms of both output and quality.

A higher level of operational flexibility and improved consistency has been maintained. Overall better efficiency allows for lower operating costs. And easy, predictable maintenance add further benefit to the bottom line. The Phoenix based cement producer is completely satisfied with the installation of a VRM for cement grinding.