Industry Reports

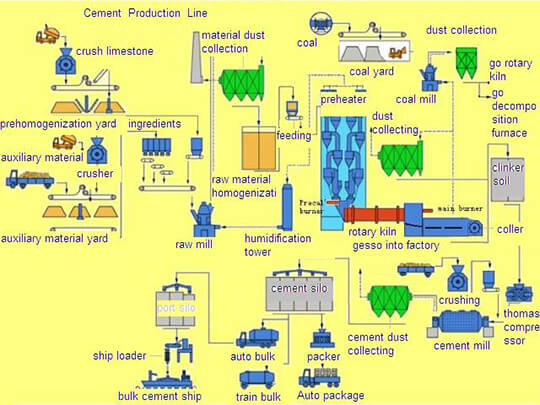

A Brief Introduction to Cement Production Line processing

Cement production line is short for cement making production line,it is a production line composed by a complete set of cement equipments, which mainly include cement rotary kiln, cyclone preheater and grate cooler. The cement making process is mainly composed by crushing and prehomogenization, preparation of raw materials, preheating and precalcinating, calcinating of cement clinker and packaging of cement powders.

Cement Making Plant

The silicate cement production technology is representative of the cement machine, and it uses limestone and clay as the main raw materials, after crushing, burdening and grinding, the raw material is sent to the cement rotary kiln to be burnt to become clinker. Then gypsum is added to it and the clinker will be ground to become the final cement. Due to the difference of manufacturing methods of raw materials,

The Main Cement Equipments Used in Cement Making Production Line

(1) Cement rotary kiln is a main machine used for calcinating cement clinker and it has been widely used in cement, chemistry,and metallurgy . This cement rotary kiln has simple structure, reliable operation and easy control of the production process.

(2) Cyclone preheater is suitable for being equipped with various kiln types and it can be widely used for the construction and renovation of large, medium and small-sized cement plant.

(3) Grate cooler is quenching cooler whose working principle is that use the air blower to blow cold air to quench the stratiform clinker on the grid plate, making the temperature of the clinker plunge from 1200℃ to below 100℃.

Two cement making process method :dry method and wet method.

(1) Dry type cement making production technology. As for this production technology, the raw materials are dried and ground at the same time, or first dried and ground to become powders and then fed into the dry kiln to be burnt to become clinker.

(2) Wet type cement making production technology. As for this production technology, the raw materials are ground with water to become slurry, and then fed into the wet kiln to be burnt to become clinker.