Industry Reports

Technology and advantages of CHAENG active lime production equipment

With its rich experience in lime production equipment and strong sense of social responsibility, CHAENG(Xinxiang Great Wall Machinery Co., Ltd ) became a new member and partner of China Lime Association in April 2016. In July 2016, the active lime production line with annual production of 400,000 tons established by CHAENG was in commission.

In China, lime industry is a sunrise industry. The developed countries in the world all have made steel with active lime and using active lime in converter steel-making is a basic technical policy, in addition, active lime is used in liquid steel refining and the sintering process of iron ore, which also gets good results. And now, the quality of active lime attracts more and more focus from metallurgical industry and other industries.

CHAENG possesses near 60-year experience of researching and manufacturing large rotary kiln. In 2014, it successfully established an EPC active lime kiln production line with annual production of 400,000 tons for Guangxi Huayan, which was reported by many medium in this industry including China Building Materials News and Guangxi TV station.

Lime kiln technology of CHAENG:

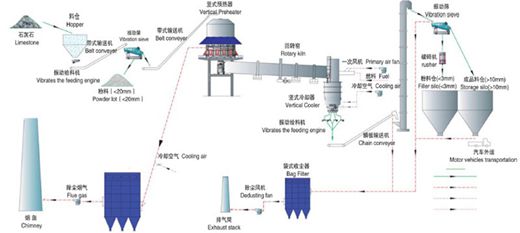

The qualified limestone (20 ~ 50 mm) is lifted by bucket elevator to preheater’s top silo where there are two level indicators (up and down) controlling the feeding amount , then the limestone is separated evenly into preheater’s all rooms. In the preheater, the limestone is heated to about 900℃ by 1150℃ kiln flue gas, and about 30% of it is decomposed, and then hydraulic push rod pushes it into the rotary kiln where limestone is decomposed into CaO and CO2.

The limestone obtained from decomposition is delivered into the cooler where the limestone’s temperature drops below 100℃ under the cold air and then it is released. The hot air (600°C) after heat exchange enters into the kiln and mixes and fires with coal gas. After the exhaust gas is cooled by passing through the multi-pipe cooler, it enters into the bag filter through the blower, and then enters into the chimney through the exhaust blower.

The lime coming out from the cooler is delivered into the finished lime warehouse successively through vibration feeding machine, bucket chain conveyor, bucket elevator and belt conveyor.

Advantages of EPC lime kiln of CHAENG:

1. Large output. The maximum production can reach 1500t/d for a single line;

2. The quality of lime products is even, and the insufficient calcined and over-calcined ratio is lower than 8%;

3. The activity of the lime is up to 400ml;

4. The system is energy saving and environmental friendly.

5. Have high degree of automation, and the whole line adopts DCS remote control system and it only needs 2-3 operators to operate it.

EPC service of CHAENG

CHAENG firstly adhere the EPC concept to “one piece of equipment and eight services” in the industry in China, and it not only can manufacture single main machine and parts, but also can help clients to have raw material test, project design, equipment manufacturing, installation, commissioning, technical training, reaching standard and quality and EPC production, which really make clients satisfied with our products and services.