Industry Reports

200 TPD-1500 TPD Small to Medium Size Cement production Plants project

Chaeng is known all over the world for manufacturing Cement Plants based on NSP processing and Rotary Kiln Technology. We offer Small to Medium Size Cement Plants (Capacity varying from : 200 TPD to 1500 TPD ) on turn key basis and have capabilities to undertake all aspects of the project from :- Raw Material Analysis ---Project site Inspection ---- Designing Plants based on Individual requirement ---- Civil Foundation Work ---- Erection and Commissioning of the Plant and Machinery ---Training of the Staff.

Salient Features:

Low pressure drop pre heaters.

Raw mill equipped with High efficiency separator.

Raw Meal blending in CFC silo.

Pre-calciner suitable to work with alternative fuels.

Inlet & discharge fitted with Efficient seals.

Benchmark cooler design.

Benefits:

Near Zero Maintenance.

Operation of Plant is Simple.

Gestation period is short.

Greater efficiency in Power Consumption.

Abundant fuel savings.

Low Installed cost.

Trusted and proven Trouble free Technology.

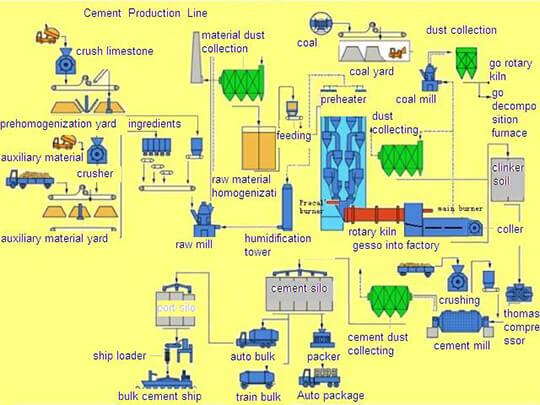

Cement Manufacturing Process

1. Crushing & Proportioning:

Limestone rock is the principal raw material, the first step after quarrying in the processes is the primary crushing. Mountains of rock are fed through crushers capable of handling pieces as large as an oil drum. The first crushing reduces the rock to a maximum size of about 150 mm. The rock then goes to secondary crushers or hammer mills for reduction to about 75 mm or smaller. After that the material is stacked with the help of a stacker and reclaimed with the bridge type reclaimer in a cross section so that the homogeneous limestone is fed further in the process, thus averaging the limestone quality.

2. Raw grinding & Blending:

The next step in the process is to grind the above particles to a size of 90 microns or less which is done in a raw mill, a closed circuit ball mill equipped with high efficiency separator. After achieving the 90 microns size the fine grinded material also known as raw meal is sent to the continuous blending silos (CFC) for homogenization & extracted by means of load cell hopper for the next step which is feeding to the kiln pre heaters

3. Pyro processing:

The raw material is heated to exceeding 1,450 C (2,700 degrees F) in 5 or 6 stage pre-heater tower (about 110 metres in height) in the suspended form, than through a pre-calciner and finally in a huge cylindrical steel rotary kilns lined with special firebrick. Kilns are frequently as much as 3.7 M (12 pi) in diameter, large enough to accommodate an automobile and longer in many instances than the height of a 40-story building. Kilns are mounted with the axis inclined slightly from the horizontal. The finely ground raw material or the slurry is fed into the higher end. At the lower end is a roaring blast of flame, produced by precisely controlled burning of powdered coal, oil or gas under forced draft.

4.Clinker Cooling and Heat Exchange with Air :

As the material moves through the kiln, certain elements are driven off in the form of gases. The remaining elements unite to form a new substance with new physical and chemical characteristics. The new substance, called clinker, is formed in pieces about the size of marbles. Clinker is discharged red-hot from the lower end of the kiln and generally is brought down to handling temperature in Grate coolers. The heated air from the coolers is returned to the kilns, a process that saves fuel and increases burning efficiency

5. Cement clinker grinding, Storage & Packing:

Portland cement, the basic ingredient of concrete, is a closely controlled chemical combination of calcium, silicon, aluminum, iron and small amounts of other ingredients to which gypsum is added in the final grinding process to regulate the setting time of the concrete. Lime and silica make up about 85% of the mass. Common among the materials used in its manufacture are limestone, shells, and chalk or marl combined with shale, clay, slate or blast furnace slag, silica sand, and iron ore.