Industry Reports

1 million tons per year cement grinding station production processing

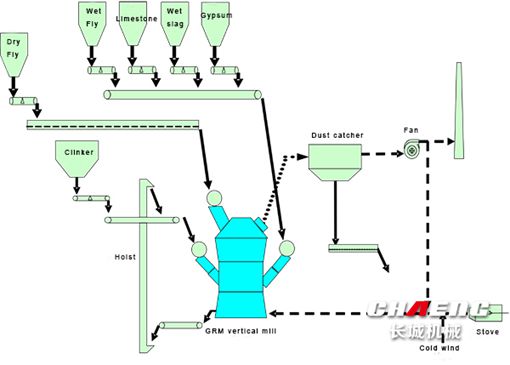

1 million tons per year cement grinding station production line using a vertical mill grinding technology, after several months of commissioning the production, the production of more stable grinding station, reaching high-quality, high yield, low consumption purposes.

The main production equipment and technology:

1. clinker grinding production line design. Gypsum,clinker rotary kiln , limestone weighed by the belt, with a good mixture by belt conveyor to the elevator into the steady flow weighing bin, the process material through a magnetic separator to remove metal, followed by mixing the feed roller press, extrusion material through all cake elevator, into the beaten grader, greater than 2.5mm thick material into the steady flow weighing bin, then mix together with the feed roller extrusion presses, less than 2.5mm fine material then enter the mill grinding, grinding of materials with a good measurement of fly ash by grinding the mixture into the tail conveyor chute hoist, selected by powder delivery chute into the inner loop separator, separator meal mill back again, the fine powder through the air delivery chute into the finished hoist into finished products. After a grinding mill dust tail gas purification dust into the atmosphere by the exhaust fan, the collection of fines into the mix elevator.

2. slag grinding production line design. Gypsum, dry slag, fly ash, metered by the belt, with a good mix through the elevator into the mill grinding, the process material through the separator to remove magnetic metal, the grinding material through the grinding end delivery chute mix into the elevator, was selected by the powder into two parts delivery chute for efficient superfine classifier, classifier mill meal back again, and finished cement by air box pulse bag filter collected powder into finished products by air slides hoist into finished products. The grinding of superfine dust and gas as special high efficiency separator selected primary air powder, fresh air is used as separator of two or three selected wind powder, dusty gas through the air box pulse bag filter purified, by the exhaust fan into the atmosphere.

3. The hybrid design of slag powder and clinker powder. In separate grinding production process, clinker and slag powder, fine powder addition to meeting the givers, we must also pay attention to accurate metering and mixing evenly these two issues. So we chose the spiral measurement known as metering equipment, and the choice of air delivery chute, not only as a mixing device, but also as a delivery device. Wherein said helical metering by the overflow pipe single screw and metering screw single tube, the former from the steady stream role in ensuring uniform feeding in a timely manner, the latter measure, to ensure stable and accurate measuring; air delivery chute as is the use of fluidized principle of transportation of materials, so that the material in the transportation process, slag and clinker powder kept tumbling, stirring.