Industry Reports

Technical characteristics of the active lime kiln equipment

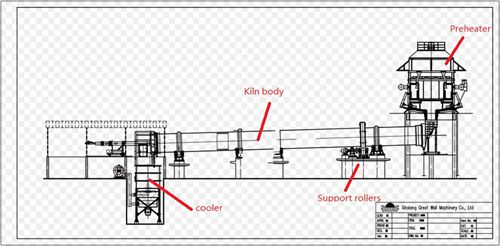

Active lime rotary kiln main technical characteristics are as follows:

1, the installation of a vertical preheater kiln, so kiln flue gas heat conduction directly to the limestone, flue gas temperature can be reduced to below 235 ℃, effectively recycling the exhaust emissions of the heat away, but also for subsequent removal to reduce the load.

2, the rotary kiln from the traditional aspect ratio of about 2O reduced to 14 to 15. Shorten the length of the kiln surface not only reduce heat loss to the surrounding, also reduces the footprint of the device.

3, the kiln head was cooled using a vertical cooler alternative to the original vertical cooling tube. Avoid lime sensible heat loss. Hot lime kiln from falling through the secondary air heat exchanger and into the drum, the lime is cooled after the air absorbs heat into the rotary kiln temperature combustion.

4, a cooler and kiln hood with integrated vertical design, small size, good sealing, to avoid the hot exhaust gas fugitive emissions.

5, combustion air is divided into primary and secondary air. Directly involved in the primary air combustion, secondary air for the cooling air. Primary and secondary air are supplied by a separate fan. This design can be secondary air temperature rose above 600 ℃, as combustion air, in order to save fuel provide favorable conditions.

6, using a dedicated combustion system to the rotary kiln heating. In addition to the use of pulverized coal as a fuel can also be used alone outside the low calorific value gas (such as producer gas, calcium carbide exhaust, semi-coke gas) calcined as fuel to be supplied simultaneously using a variety of fuel use. The calcination temperature can be adjusted by adjusting air and gas flow.

7, measures to improve environmental protection. Calcination exhaust using pulse jet bag filter dust, to meet the national emission standards. In the vertical blanking point cooler it is also used baghouse dust.

8, high level of automation. Calcining system equipment manufacturing operations adjustment, control and alarm in the main control room centralized control by PLC, and a screen display of the control points and the necessary interlock monitoring of the operating parameters in the production process used for automatic recording, and ready to print.