Industry Reports

Slag Powder Application in Cement Concrete

Because of modern engineering and construction make request on the performance and quality of concrete,technical requirements, following after chemical admixtures in the concrete universal application engineering, active mineral admixture of fine materials and engineering increasingly at home and abroad has aroused widespread concern and attention, and even called it the sixth component of concrete, concrete technology advances become an important means and measures. Ideal active mineral admixtures was undoubtedly fine granulated blast furnace slag water quenching, because both cementitious and pozzolanic activity, therefore, in recent years in cement and slag powder in concrete has made great progress.

Slag powder is granulated blast furnace slag water quenching after grinding to achieve a predetermined powder material fineness. Application of cement and concrete, both as a cement admixture, can also be used as concrete admixture. Its role and now cement production by country standards allow cement mixed with 20% to 70% blast furnace slag Portland cement is quite different.

Concrete production of new technology, slag powder can be used cement. Not only it has good economic benefits, but also significantly improved, improve the overall performance of concrete, such as: improving the working of concrete, reducing the heat of hydration temperature, improve the internal structure of concrete, improve the corrosion resistance of concrete and durability of concrete and late strength increase and so on. Since the slag powder on properties of concrete has good technical results, therefore, foreign countries also have called it an auxiliary gelling materials, not only as a component of the material to the preparation of high-strength, high-performance concrete, but also very suitable for medium-strength concrete, Mass in the harsh environment of concrete and durability requirements of concrete projects.

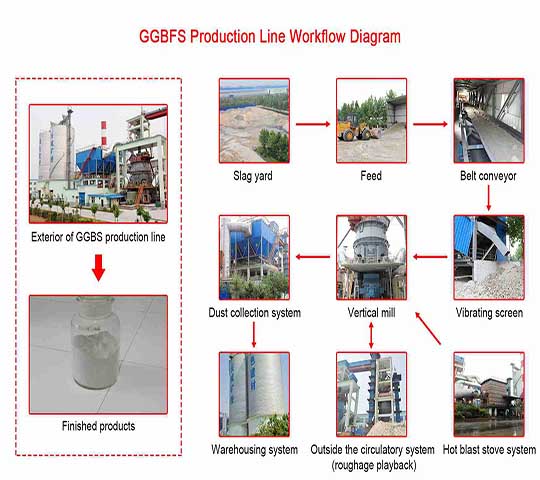

the most common processing equipment is a vertical roller mill for slag processing, CHAENG(Great Wall Machinery) vertical roller mill, its technical performance directly affects the grinding performance and milling process. Vertical slag grinding mill can use hot stove provided to achieve the drying and grinding process, qualified slag powder into the slag powder silo. Save slag dryer, simplifying the production process. Clinker, gypsum or other mixing timber with a closed circuit ball mill grinding system, qualified powder into the clinker, gypsum powder silo. Great Wall Machinery currently has a mature and reliable high vertical roller mill grinding slag technology and equipment, most of the large steel companies around the world use this system for slag powder production.