Industry Reports

CHAENG vertical roller mill realize slag powder used in concrete

Vertical mill can be used in a variety of ore powder processing of materials , ore production process will produce a certain amount of slag, after a long period of accumulation, not only occupy land resources, but also pollute the environment, so , slag processing has always been a serious problem. With the upgrading of the relevant national technical equipment, the slag has also been a corresponding application, which is turning waste into treasure. Among them, the slag can be processed into different fineness slag powder by vertical mill , and then applied in many industries, which slag powder in concrete to have a good application.

Slag powder can be substituted with the same amount of cement mixing concrete to improve the workability of fresh concrete, according to the different using requirements of concrete, slag powder can be substituted with the same amount of 30-70% of cement per cubic meter of concrete will reduce production costs 15- 30 RMB, other admixtures not achieve this benefit. Further, since the ratio of water demand of slag powder and cement, slag powder can reduce the incorporation of water-cement ratio of concrete, reduce bleeding of concrete water, increase liquidity, improve workability, pumpability, and therefore maintain a good working properties.

Since 30-70% can be substituted with the same amount of cement, reduce the heat of hydration of cement during hydration total calories will be reduced, thereby reducing the temperature of the concrete, to avoid the concrete due to excessive temperature rise caused by the cracking of the concrete .

Without changing the water-cement ratio, the slag powder with 30-70% of the amount of cement replacement, early strength concrete will decrease. But slag powder demand water smaller than cement, water-cement ratio can be reduced in practice, to achieve the same slump in the case, the early strength of the concrete will not actually fall. In actual member, due to internal temperature rise will lead to concrete strength. However, after the incorporation of slag powder, concrete temperature conducive to the development of strength, the higher the temperature the faster development of strength, so the actual members can improve early strength, late strength increase faster than pure cement concrete, especially in 60 days 、90 days, even the strength of the concrete as well as substantial growth a year later.

After the incorporation of slag powder, while reducing the amount of cement, thus reducing the internal factors of corrosion; on the other hand, since the slag powder particles finer than cement, can be uniformly dispersed in the cement slurry, the particles rehydrated fill in the gap in cement, concrete pore structure is improved, gradually reduce the permeability of concrete, effective inhibition of alkali aggregate reaction, improve sulfate resistance, enhanced resistance to seawater corrosion. Overall, improved resistance to chemical corrosion and enhance the durability of concrete.

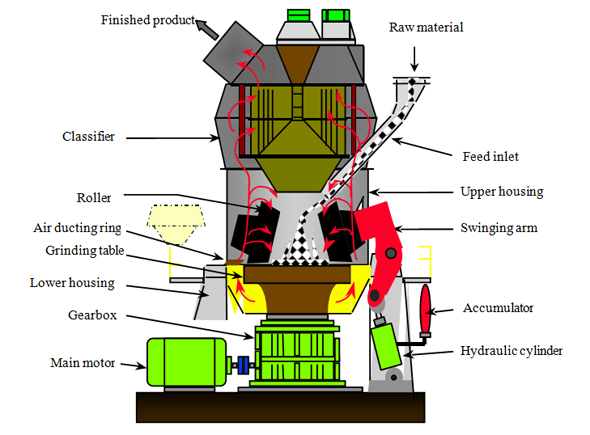

The reason could be so good slag powder in concrete application, this is a credit to the vertical mill, the mill processing slag into concrete desired particle size of slag powder, and then merging and other materials to complete the concrete produce. In short, the vertical roller mill equipment to achieve the application of slag powder in concrete. At present, the CHAENG vertical grinding machine equipment has been widely used in the production of slag powder, which will realize more value slag powder.