Industry Reports

Deep processing of slag powder recycling,vertical mill exert energy saving effect

With the development of China's steel industry, iron and steel slag emissions increased year by year, a large amount of slag is not processing, it will generate dust, pollution of the atmosphere; if discharged into the river system can cause blockage of the river, and one of the toxic chemicals will be on human and biological hazard. Chaeng(Great Wall machinery) believes that the slag is one of the larger industrial waste emissions at present our country, how to use its resources, should deep processing using vertical mill.

Slag utilization, turning waste into treasure, variable harm into, has become an important technical and economic policy in China's economic development, is an important means of solving environmental pollution of China's steel production, the contradiction between the lack of resources, as well as iron and steel production one of the tasks facing the settlement.

slag powder after drying, grinding to powder fineness appropriate. After mixing slag powder in concrete, can reduce concrete aggregates (sand, stone, etc.) concrete volume expansion caused by the thermal cracking reaction; more in the slag powder ettringite crystals can reduce the porosity of concrete, thereby reducing chlorine ion penetration, forming a protective layer on the steel corrosion; reduce the amount of cement tricalcium aluminate and soluble calcium hydroxide, thereby reducing the expansion due to the concrete sulfate attack due to improved pumping concrete slump job losses, improve the late strength of concrete, has good durability, corrosion and wear resistance, especially for the configuration of high-grade, high-performance concrete.

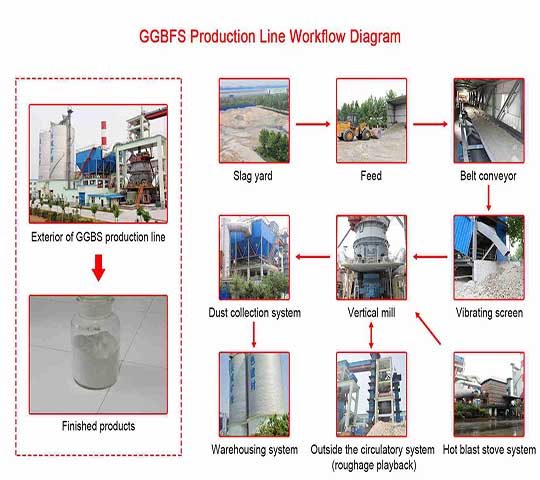

Slag powder with excellent performance, as high-quality concrete admixtures, concrete is more and more appreciated by concrete manufacturers and builders . In the energy saving and environmental protection, the principle of sustainable development, the use of vertical mill processing slag Solutions will fully cover our steel plant slag powder processing.

As a Chinese famous cement equipment vertical mill, tube mill, rotary kiln manufacturer, Great Wall Machinery Co., Ltd. in response to the call of the solid waste disposal States, invested heavily in research and development of high-tech equipment - slag vertical mill. It is reported that Great Wall Machinery Co., Ltd. production of slag vertical mill with low energy consumption (system power consumption does not exceed 42kWh / t), excellent production quality slag (specific surface area of up to 430 m² / kg, 7 Tian activity indicators have reached around 100% ) and other characteristics, is the first choice for deep processing of slag recycling.