Industry Reports

600,000 tons of slag powder production line complete set of equipment technical parameters

Steelmaking slag is discharged from impurities, the annual amount of slag discharged in more than 80 million tons of steel slag recycling in recent years more and more national attention. Due to the large slag toughness, grinding harder than slag, slag while the iron grains are more prone to inefficiency, high consumption, this level of technology for slag handling equipment will be put forward higher requirements.

First, what kind of steel slag production line technical process best?

Factors influencing slag powder production system performance indicators are: 1, slag grinding fineness; 2, energy consumption level; 3, in addition to iron levels; 4, whether the system is running more stable and reliable; 5, pollution emissions, etc. This It will directly affect the economic efficiency of enterprises and the comprehensive utilization of slag.

In response to these factors, the Great Wall Machinery Co., Ltd. Xinxiang City, breaking the traditional ball mill grinding process, the introduction of international advanced level of "pretreatment + vertical mill" technology, which uses a rod mill and roller mill grinding equipment and live as a pre-grinding equipment, play an extremely obvious advantages:

1. The specific surface area of slag powder reasonable.

Great Wall Machinery vertical mill production of steel powder specific surface area of 450 ~ 500m2 / kg is appropriate, this time better activity, energy consumption indicators over.

2. Li mill system power consumption significantly lower than in the milling system.

Mill energy consumption is too high for many cement companies had a headache, and the new vertical mill equipment has become the most internationally recognized technology leader in energy saving grinding equipment, stand-alone energy consumption can be reduced by more than 30%!

3. less dust.

We know that because the system processes mill complex, requiring multiple devices and multiple conveyor, it will cause severe dust pollution. The slag vertical mill vertical mill set conveying, grinding, drying, choose powder in one, fully enclosed design, but also the Great Wall mechanical shaker framework, in addition to feeding floor frame is equipped with dust collectors, dust truly " 0 "emissions. )

The high iron selection rate and improve economic efficiency.

Slag generally ranging from 1% to 3% iron content, the Great Wall machinery vertical mill grinding system iron election process optimization, the feeding system to increase multi-channel Separators, greatly increasing the amount of metallic iron elect improves system integrated economic environmental benefits.

5. lead slag belt, reduce roller wear.

Slag belt to take the most advanced flat belt feeding device overlay technology that enables hanging on a belt of more effective magnetic separator selected iron-containing material discharged from the mill, the mill again prevent, reduce roller wear.

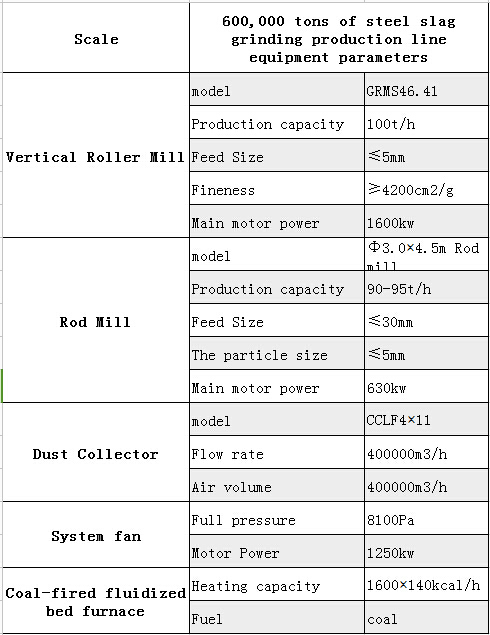

Second, the Great Wall Machinery 600,000 tons of slag powder production line a full set of equipment, technical parameters

According to the survey, an annual output of 600,000 tons of steel slag powder production line has become the mainstream market, slag production line capacity, annual Great Wall Machinery leading 600,000 tons of slag powder production line a full set of equipment technical parameters:

In addition to an annual output of 600,000 tons of steel slag processing line, we can also provide an annual output of 300,000 tons of steel slag powder production line, with an annual 450,000 tons of steel slag powder production line and an annual output of 1 million tons of steel slag powder production line a full set of equipment, particularly equipment technical parameters, consult the online customer service, we will have professional regional managers to provide you with the most efficient and quality service!

Third, the Great Wall of mechanical vertical steel slag production line applications in the iron and steel project in Xuzhou

2010, Xuzhou City, the Great Wall of steel in cooperation with the Xinxiang construction machinery company a slag powder production line project, design capacity of 600,000 tons / year, using the most advanced stand mill equipment, the rear ground steel slag processing, as incorporated in the mix cement or concrete, significantly increased its strength, impermeability degrees, frost resistance. After the expected completion of the project will be around in the major cement plant in Xuzhou, mixing station selling, and will be widely used in key projects in the province.