Industry Reports

Ceramic sand kiln - new ceramic kiln

First , Introduction:

Ceramic sand: ceramic sand, by definition, ceramic particles, called fine sand, also known as oil fracturing proppant.

There are too many varieties of ceramic production of ceramic raw materials. Ceramic sand kiln is widely used in clay, Wong, river sludge, fly ash, shale, slag, dolomite, kaolin, bauxite, refractory charge, cement, limestone, titanium-iron powder, bauxite ore, charcoal , coke, ore, alumina, magnesium oxide, zinc oxide, cement and other special ceramic materials firing and production.

Second , the production process:

1. crushing and grinding: the dry coarse material is crushed and milled

2. Calcification: polished, these materials will enter the preheater kiln (cylinder end), and then by the special secret tube into the kiln. Heat is injected by the burner is injected into the kiln bucket. Due to the tilt cylinder rotates slowly, the material in the direction of the roll ring calcination reaction, have passed the calcination section, the reaction section, decomposition section.

Note: the exhaust gas heat-exchanged into the atmosphere by the exhaust fan.

3. Cooling: material discharged from the rotary kiln into a cooling device for cooling

4. Screening: large size material will be shipped back and deal with

Three , ceramic kiln features:

Great Wall Machinery ceramic sand kiln having a Simple structure, easy to control during production of reliable, less wearing parts, high operating rates, solid structure, smooth operation.

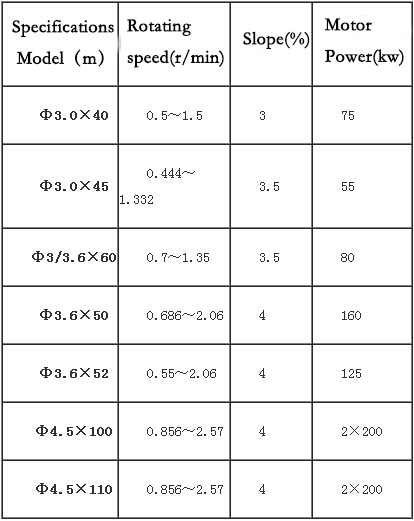

Fourth , technical parameters: