Industry Reports

Steel slag grinding in industrial use

Steel slag is produced during the separation of the molten steel from impurities in steel-making furnaces. The slag occurs as a molten liquid melt and is a complex solution of silicates and oxides that solidifies upon cooling.Steel Slag is a valuable resource for society. Blast furnace slag which is naturally cementitious for the cement industry.

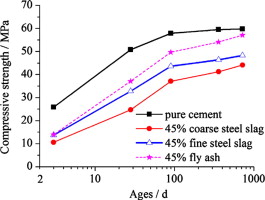

A super-fine steel slag with the specific surface area of 786 m2/kg was prepared by mechanical grinding. Its cementitious properties were investigated by comparing the results obtained from it with those obtained from ordinary steel slag, fly ash, and cement. The results show that the super-fine steel slag exhibits a much higher activity at early and middle ages but a lower activity at late ages than the ordinary steel slag. Though the specific surface area of the super-fine steel slag is much larger than that of cement, the activity of the super-fine steel slag is still obviously lower than that of cement. The super-fine steel slag replacement tends to weaken the cementitious properties of the composite binder. As compared to fly ash, the super-fine steel slag tends to make more contributions to the hardening of concrete at early ages but far less contributions at late ages. Overall, it seems that it is uneconomical to produce super-fine steel slag by mechanical grinding.

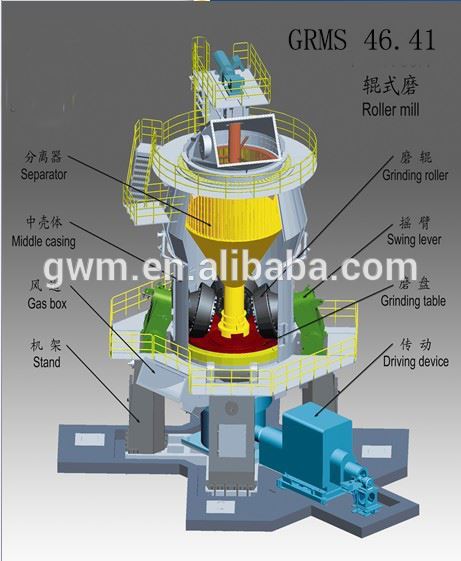

The product of the Great Wall machinery production steel slag vertical roller mill is the equipment to grind Ground Granulated Blast furnace Slag into small particles.steel slag(fineness:4200-4500cm2/g) produced by vertical roller mills are being used to substitute clinker in conventional cement manufacturing as well as to partially replace OPC for ready-mixed concrete production, for which the percentage of GGBS usage is typically at 10-15% and 20-25% respectively.

The product of the Great Wall machinery production steel slag vertical roller mill is the equipment to grind Ground Granulated Blast furnace Slag into small particles.steel slag(fineness:4200-4500cm2/g) produced by vertical roller mills are being used to substitute clinker in conventional cement manufacturing as well as to partially replace OPC for ready-mixed concrete production, for which the percentage of GGBS usage is typically at 10-15% and 20-25% respectively.