Industry Reports

How to Make Full Use of Waste Heat of Cement Line

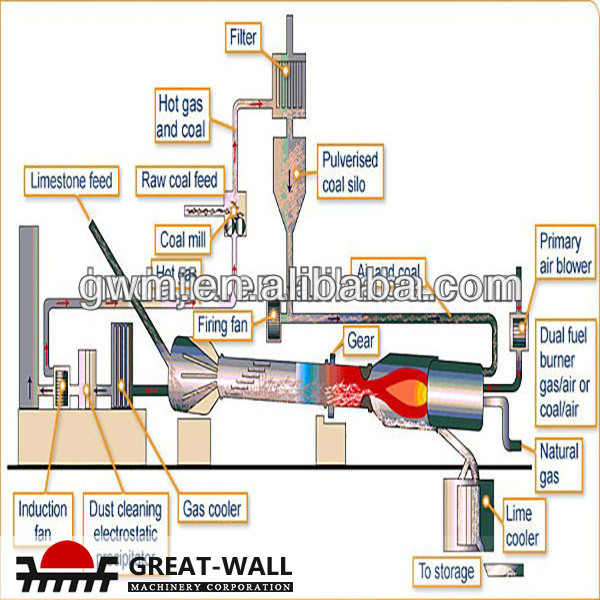

During the cement manufacturing process, qualified raw material and fuel are weighed by electronic weighers with 3‰ accuracy, then mixed evenly by skips and belt conveyers. The single-skip hoist with 1.5 m3 will convey the mixtures to top silo. The electric vibrating feeder will convey the materials evenly with a fixed quantity. The top rotary distributor will distribute the materials. Then materials will move downwards basing on its gravity against the coal gas through preheating part, calcining part and cooling part.

There is complex heat exchange between falling materials and hot coal gas, along with raw materials’ decomposition and grain changes. When this process completed, the hot air falls to about 40—60℃. The clinker is discharged to outer belt conveyer by disk ash machine and two-cabin seal valve with no leakage of combustion air. The clinker of ≤5mm and >5mm will be discharged into different hoppers through elevator and screen.

The application of waste heat from cement line can save energy and realize environmental protection, also respond to our countries call for save energy and reduce emission.