Company News

The relationship between grinding efficiency of ball mill and filling rate and material

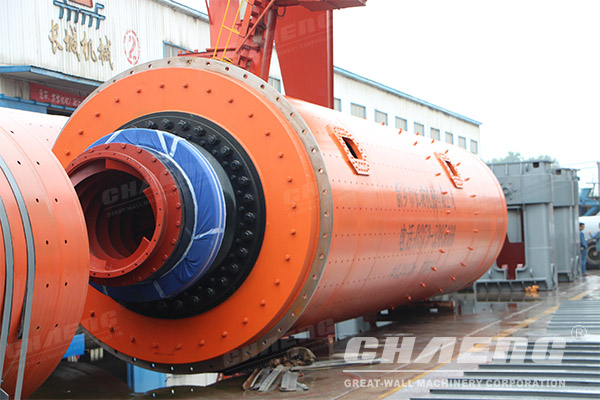

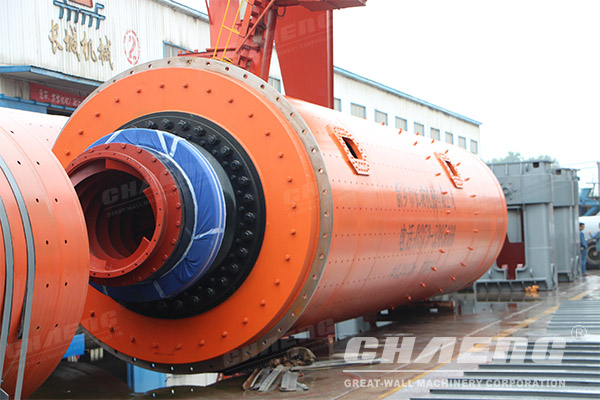

Ball mill is a commonly used equipment for grinding powder in mining machinery and equipment. It can process various materials such as slag, steel slag, limestone, and cement. The grinding efficiency of the ball mill directly affects the economic indicators and later operation efficiency of the entire dressing plant. If you want to improve the grinding efficiency, you must first understand the relationship between the filling rate of the grinding ball and the material!

The relationship between the grinding efficiency of the ball mill and the filling rate of the grinding balls

The ball filling rate of the ball mill refers to the ratio of the volume of steel balls added to the mill to the volume of the inner chamber of the ball mill, which determines the strength of the grinding effect. The more balls are loaded, the more times of blows, the larger the grinding area, the stronger the grinding effect, the higher the productivity, but the higher the power consumption; on the contrary, the less balls are loaded, the weaker the grinding effect, the lower the productivity and the less power consumption. The filling rate of steel balls of the ball mill is related to the rotational speed of the ball mill and mutually restricts each other. Under different filling rates, the rotational speed of the steel ball from falling down to falling is different. In production practice, the filling rate corresponding to the ideal productivity should be found through experiments, and the larger the diameter of the ball mill, the lower the filling rate of steel balls, so the medium filling rate should be correspondingly reduced for large ball mills

The relationship between the grinding efficiency of the ball mill and the material of the grinding ball

As we all know, ball mills consume a lot of grinding media, and it is of great significance to improve the wear resistance and prolong the life of the media, and the material of the grinding media directly affects the grinding effect and economic benefits.

At present, the materials of grinding media are mainly metal materials, including steel media, alloy steel media, cast iron media, etc., which can be subdivided into low-chromium cast balls (containing 0.5-2.5% chromium, 1.8%-3.2% carbon), medium Chromium cast balls (3%-7% chromium, 1.8%-3.2% carbon), high chromium cast balls (10% or more chromium, 1.8%-3.2% carbon), forged balls, hot-rolled steel balls, etc. Forged steel balls have high impact toughness, low breakage rate, and are not easily deformed. Hot-rolled steel balls have precise dimensions, rounded geometry, high hardness, good mechanical properties, and wear resistance, not easy to deform and crack. Generally, cast balls are suitable for dry grinding and forged balls are suitable for wet grinding. Forged balls are the most commonly used ball mill grinding media in the world, and hot-rolled steel balls are gradually replacing cast balls as high-quality ball grinding balls. The choice of materials is mainly based on the material to be processed and the economic situation of the enterprise.

The above is an explanation of the relationship between the grinding efficiency of the ball mill, the filling rate of the ball, and the material. I hope it can help everyone. If you have a demand for ball mills, please consult Xinxiang Great Wall mechanical pulverizer manufacturer online. Our company can provide users with grinding equipment with an output of 30-300 tons per hour, with high yield, high quality, energy saving and low consumption!