Company News

How to set up the raw material system of slag production line

1. Raw material system

2. Material return system

3. Mill system

4. Powder collection system

5. Finished product storage and transportation system

6. Lubrication hydraulic system

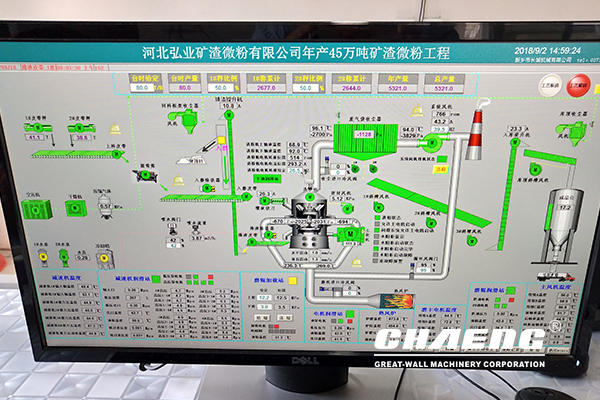

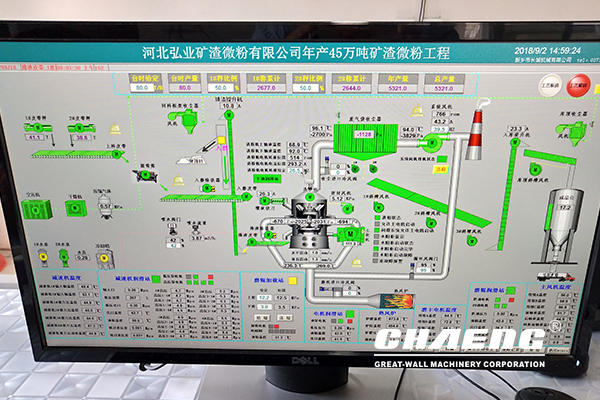

7. Hot air system

8. Electrical automation system

2. Material return system

3. Mill system

4. Powder collection system

5. Finished product storage and transportation system

6. Lubrication hydraulic system

7. Hot air system

8. Electrical automation system

The raw material vertical system includes raw material storage yard, metering feeding and grinding device. Today, the editor will tell you about the setting of the raw material yard of the raw material system

At present, the environmental protection standards and requirements are getting higher and higher. The Great Wall of Xinxiang actively responds to the national environmental protection requirements and carries out closed design of raw material stacks. Currently, there are two closed raw material storage yards with a total slag capacity of 140,000 tons. Open and bright, with direct supply and unloading, buffer unloading, fabric storage and perfect design.

Overall settings:

1. Harden and prevent leakage treatment on the ground of the yard, and design a drainage system around it.

2. Set 2 + 1 steel underground receiving hopper, feed the raw materials into the receiving hopper through the loader, and the volume of each receiving hopper is not less than 1h of usage.

3. The top surface of the receiving hopper is 100 ~ 200mm higher than the ground. The gentle slope design is equipped with a mesh screen. It has sufficient strength and firm support to meet the loader's walking and constant pattern.

4. Set the vibration motor at the corner of the mesh screen and protect it. Manual control on site + remote control of the loader driver.