Company News

Raw Mill / Slag vertical roller mill technology innovation

Powder concentrator is one of the most important part of slag vertical roller mill (hereinafter referred to as “slag vertical mill”), the function of which is to make qualified finished product after grinding enter into the precipitator through outlet piping of body by steering flow while semi-finished particle (over the specified size) will be threw out and sink under gravity. After leaving the scope of centrifugal force, they will be collected by a collector to return to the mill for grinding once again. Steering flow is formed through wind board, which make the mixture of powder and air from vertical rise to tangential flow and the fineness of the finished product depends on the clearance between wind boards, the angle of the wind board and the speed of the rotor.

1. Facing problems

Traditional wind board is fixed and nonadjustable. The controlled access of the fineness of the finished product produced by the slag vertical mill equipped with such wind board is single and the variety of the grinding materials is limited. The article will introduce a new type adjustable wind board, which make the controlled access of the fineness of the finished product diversified and easy to operate. And can also grind different kinds of materials to make the mill production diversification and bring the users more economic benefits.

Tangential to adjust the wind board or enhancing the rotor speed will produce more fine finished product after separation while reducing the rotor speed or radial direction to adjust the wind board will produce more coarse product; similarly, there is different situation when grind different materials and the fineness of the finished product needed is also different, all which can be settled by technical proposal mentioned above.

2. Improvement plan

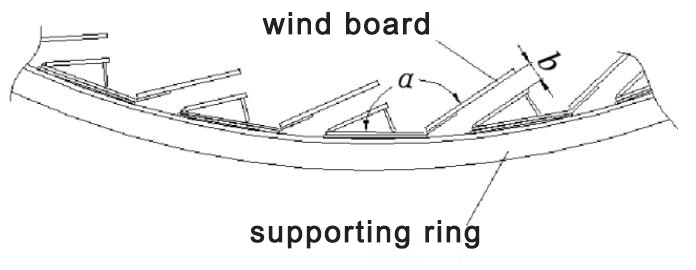

Structure diagram of traditional fixed wind board is showed in figure1

Figure 1: Structure of traditional fixed wind board

Clearance b between wind boards and self-angle α of the wind board in figure 1 are fixed value. Thus, only by adjusting rotor speed or roller pressure can achieve the different fineness of the finished product, which cannot produce the high fine finished product with high energy consumption and serious wear at the same time.

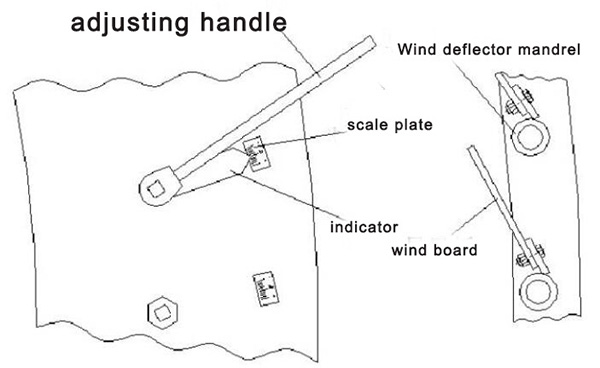

Structure diagram of new type adjustable wind board is showed in figure 2

Figure 2: Structure of new type adjustable wind board

In figure 2, the new type adjustable wind board is weld on the core shaft of the wind board, and the adjustment to all wind board device can be achieved through the adjustment to core shaft of wind board by adjusting handle and then change the clearance value between wind boards. When the fineness of the finished products meet the requirements, fix the position of the wind board and record the figure on the dial to realize the serialization of fineness value of different kinds materials corresponding to the value of the wind board position.

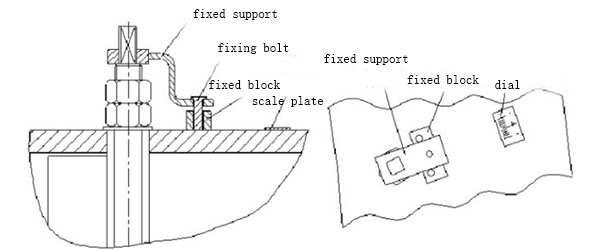

Specific fixed approach diagram of new type adjustable wind board is showed in figure 3, which is that weld the fixed support to the core shaft of the wind board and after adjusting the wind board, make fixed bolt through the hole on the fixed support and screw it in one of the screwed hole adjusting the position on fixed block (weld on the body on the spot). The advantage of the fixed way is that lock nuts above the wind board will not be loose by the vibration of slag vertical roller mill and cause the position shift of one of the wind board. In addition, screwed hole adjusting the position on fixed block realize the adjusting function of the wind board and make the clearance value between wind boards adjustable.Figure 3: Fixed approach diagram

3. Reforestation effect

Currently, the equipment has been used on a 5.6m slag vertical roller mill of a building material company in Indonesia at the end of 2016. By adjusting the new type wind board reasonably, vertical mill can achieve or even surpass the design production when grind different kinds of materials. The using effect is good.