Company News

Xinxiang Great Wall early slag production line construction to achieve a good start

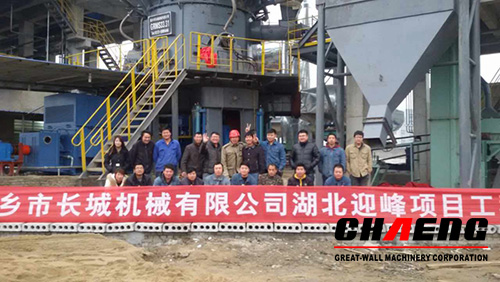

January 12, 2016, Environmental Protection Co., Ltd. Hubei Ying-feng, chairman of the inscription banner personally presented to the Xinxiang City, the Great Wall Machinery Co., Ltd. Xinxiang Great Wall in Hubei meet peak annual output of 300,000 tons of slag production line construction in superb technology, engineering quality and services expressed heartfelt admiration.

The project in September 15, 2015 the project was officially launched, January 5, 2016 put to trial, all the duration of more than three months.

When presented a banner, Hubei Ying-feng, chairman, said excitedly: "The Great Wall is not only advanced mechanical vertical mill technology, and the service is perfect, let us worry a lot!"

Project Overview

Project Name: Hubei meet peak annual output of 300,000 tons of slag powder production line

Project Company: Environmental Materials Co., Ltd. Hubei meet peak

Project Address: Hubei

Equipment Supplier: Xinxiang City, the Great Wall Machinery Co., Ltd.

The host device: GRMS33.31 slag vertical mill

Projects:

Production Line Advantages:

1.low investment cost, intelligent control

GRMS33.31 vertical mill grinding system sets of slag crushing, drying, grinding, separator, conveying in one compact layout, covering about 50% of the milling system, and may open layout, greatly reducing investment costs; equipment there PLC / DCS automatic control system, remote control, easy to operate.

2.system-on electrical energy consumption of no more than 30 Kwh, will be in the end saving

The system host horizontal disc and a tapered roller to ensure that the material is capable of forming a stable material bed, low energy consumption, compared with ball mill system savings of 30% to 40%, Hubei meet peak save a lot of energy costs.

3.less dust emissions, environmental dispel customer concerns

The whole system vacuum operation, no dust spills, clean environment, to meet the national environmental protection requirements.

4.original accessories, reducing replacement and maintenance of customer worries

The whole system grinding rolls, rocker and other spare parts are the Great Wall Machinery homemade, original production, quality assurance, reduce late customer nowhere to find spare parts problems.

5.free to adjust according to the needs of fineness, to meet different customer requirements

New efficient production line supporting cage rotor classifier, can be flexibly adjusted to ensure that the finished product than the surface area of 400 to 550㎡ / kg range, to meet a variety of customer requirements fineness;

6.tons of slag metal recycling huge profits, increase customer additional benefits

Specially designed to make pig iron unit recovery rate of 0.2-0.3% per ton of slag can get about 300-400 yuan metal revenues.