Company News

What is the design difference for Great Wall slag wertical mill and coal vertical mill

Great Wall Machinery Company 57 years working on a large kiln and mill equipment manufacturing, has become China's leading grinding equipment integrated services for both Chinese and overseas customers around the building had an annual output of 20-100 tons of slag production, excellent market reputation.

At present, the main push of Great Wall vertical mill mainly include: slag vertical mill, cement vertical mill, raw material vertical mill, coal mill and so on , in order to better meet market and customer needs, the Great Wall machinery for coal vertical mill upgrade, today, Xiao Bian take you look at the upgraded coal slag vertical mill with the original mill What are the different?

the main push of Great Wall vertical mill.

First, the same point

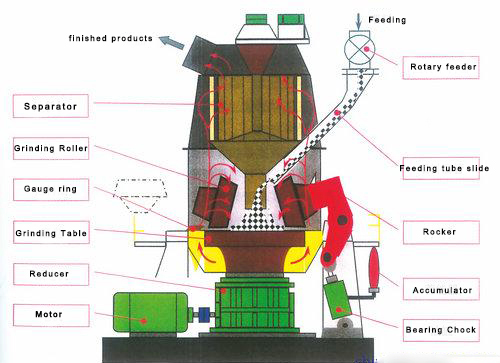

Both present the same principle Kwai, material feeding device through fall on the disc, the disc surrounding material movement under the action of centrifugal force, several roller under the force of the material is crushed. Lin after the material powder is from the hot gas through the blowing wind ring, while the coarser material blown back disc re-grinding, on the other hand thousands of suspended materials can be baked, powder by hot air into the separator grading, qualified fines are collected BU to the precipitator, substandard meal back down to the disc .

Coal vertical mill and the slag vertical mill substantially the same structure, it is mainly composed of roller, disc, shaking bamboo, splitter, transmission, chassis, roller pressure mounted antelope, roller lubrication equipment Curse on the housing limit bit devices and other components.

Second, the synchronization point

Now introduce specific coal mill and slag mill differences:

1. The form structure of the disc-shaped disc foot and tire-shaped rolls sets.

2. The roll sleeve of wear to a certain extent can be used upside down, it helps improve the coal mill production, but also reduce wear and prolong its life.

3. The bracket portion is not connected to the bridge, supported mainly by the bellows on the bracket are connected together, and the only one inlet bellows can meet equipment needs.

4. The roller mounted curse Saikawa a swap-aligning roller bearings, seal chamber extends to the outer casing, not in contact with dust and gas, so as long as you can make a simple seal roller bearing not into dust, no sealing fan .

5. mill transmission parts, does not require auxiliary transmission devices.

6. separator section is provided on the upper shell explosion-proof valve to prevent the occurrence of an explosion pulverized coal in the mill, to ensure the safe use of equipment.

7. Because coal mill less slagging, so tap outlet with cover, no need to install slagging valve.

8. roller pressing part, I loaded the cylinder's seat with the holder is no longer a whole, but by anchor bolts secured directly to the coal vertical mill basis.

Review the application of both are extensive, coal vertical mill is mainly used for electric power, metallurgy, building materials, chemical industry, milling system, particularly for burning bituminous coal grinding system.