Company News

Cement ball mill liners problems solving method

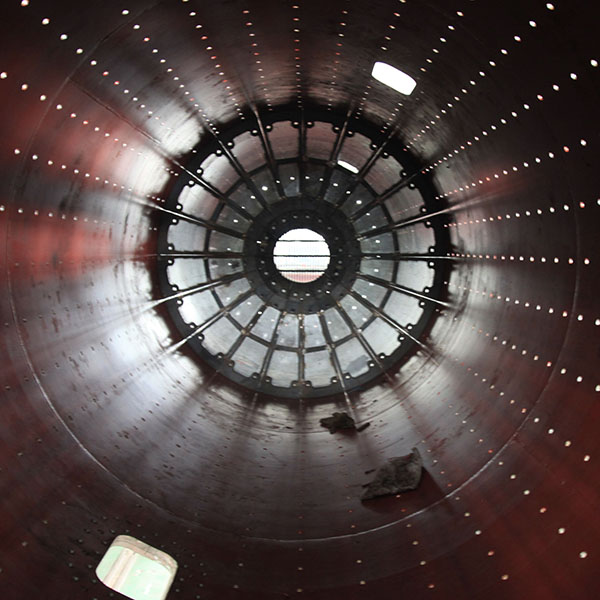

The liners are damageable parts of cement ball mill. In the working process, liner will be impacted by material constant crushing and grinding, and also by corrosion of pulp. Considering the effects of quality and hardness of mineral, liner, ball and the installation of operating conditions, liner will continue to be worn out and finally damaged. So how can we do to deal with wear problem of liners and improve the productive capacity of the mill?

1.Adjust the coal ball mill feed timely under low-load operation.

2.Design the fixed liner, tighten wedge hole into circular arc shape to avoid the stress concentration.

3.As for the ball mill with new exchanged liner, according to its characteristics, it should first use the lower hardness steel ball to run for 1~2 months, and then use higher hardness steel ball, which can increase the service life of liner.

4.Select the steel ball and liner board properly. In terms of hardness, the ratio between the ball liners and hardness should be controlled 0.85~0.9. The hardness of ball should be 1.7 times than the coal hardness. What is more, the ball diameter should be determined properly.

5.Take control of the liner installation quality strictly. If the cement ball mill liner and the cylinder do not match, it can exchange the cylinder liner or partially patching treatment

6.Control the coal quality strictly, reduce the content of coal gangue, and improve coal grind ability.