Industry Knowledge

1000 t/d lime production plant with Low Price

Introduce of 1000 t/d lime production plant with Low Price

1000 t/d lime production plant with Low Price is Low investment, short construction period, and fast standard and achievement achieved, the 1000 tpd new dry process cement production carries out the overall design concept which combines raw material preparation and clinker calcining together. Raw material preparation uses vertical mill, while the waste gas from kiln can be reused by the vertical mill for drying raw material. Thus it fully saves a lot of energy. This production line runs well and brings good economic benefit for the enterprises.

The Features of 1000 t/d lime production plant with Low Price

Simple and smooth process, compact layout

This new dry process uses three mills and one burning system. Kiln exhaust gas enters humidifier tower first, and then enters into fan, which is contrary to traditional ways. It not only saves a lot of duct investment, but also compact the layout.

Energy saving and power consumption reduction

All the material adopts mechanical transmission in order to reduce conveying power consumption. Utilization rate of cooling water cycle in the production is more than 90%. The use of exhaust gas from kiln can save more than 4,000 tons coal per year.

High automation

1000t / d new dry process production line adopts PLC control system. The system has a reasonable investment, and is very practical, advanced and reliable. It can realize distributing control functions. The operator is able to control and command production process just in the central control room.

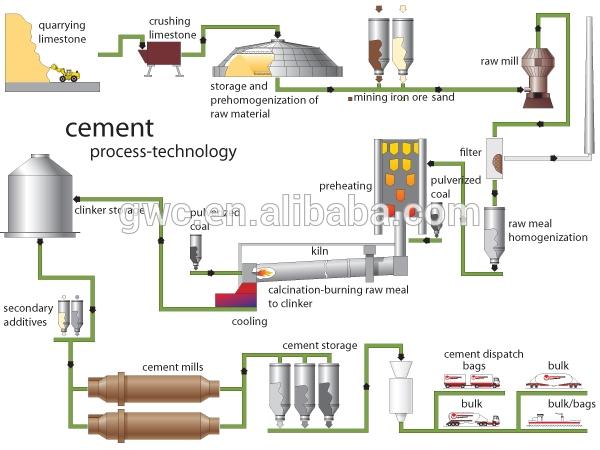

The production process of 1000 t/d lime production plant with Low Price

Cement manufacture is a multi-stage process. It mainly includes the following steps.

1. Crushing and Pre-homogenization

2. Cement Raw Material Preparation and Homogenization

3. Pre-Heating and Decomposition

4. Sintering

5. Cement Grinding and Packaging

Technical parameters of 1000 t/d lime production plant with Low Price

Company Information

Xinxiang Great Wall Machinery Corporation cover an area of 330,000 m² and having more than 1,100 employees, the company has a total asset of CNY 500 million and has passed ISO9001:2008 quality management system authentication and is a main specialized supplier for manufacturing large scale kiln mill.

Great Wall Company would like to join hands with our old and new customers and friends from home and abroad, carry out good faith cooperation and create brilliant together. We welcome friends from all circles to visit for investigation and guidance.

Why choose us?

We believe that quality is the key to success & thus, we are empowered with almost all aspects of delivering it. Moreover, we take care that all the equipment are engineered as per the latest international standard specifications & are built as per the standard shop practices, that assure for giving long life services with trouble free performance. Further, by hi-quality execution of involved job work, we have reached to a position of recognition from where, we can build on to be a front- runner in this industry.

Our Services

1.We provide you with the prophase plan, process flow design and manufacture equipment according to your special demand.

2.Send technicians to the jobsite for guiding the installation and adjustment, training operators and finishing the check and accept together with you.keep a large stock of products;

3.we can provide you with design scheme for complete production lines, spot inspection and operator training according to your demands and the conditions of applied spot, we can help you choose the right equipments.

FAQ

Do you provide after-sale service?

Yes. We have a professional after-sale service team to promptly and thoroughly solve your problems.

Do you provide equipment operation training?

Yes. We can send professional engineers to the working site for equipment installation, adjustment, and operation training. All of our engineers have passports.

How long is the warranty of your equipment? Do you supply spare parts?

Our warranty period is one year generally. We can supply spare parts.