Industry Knowledge

Coal Vertical Roller Mill manufacturers

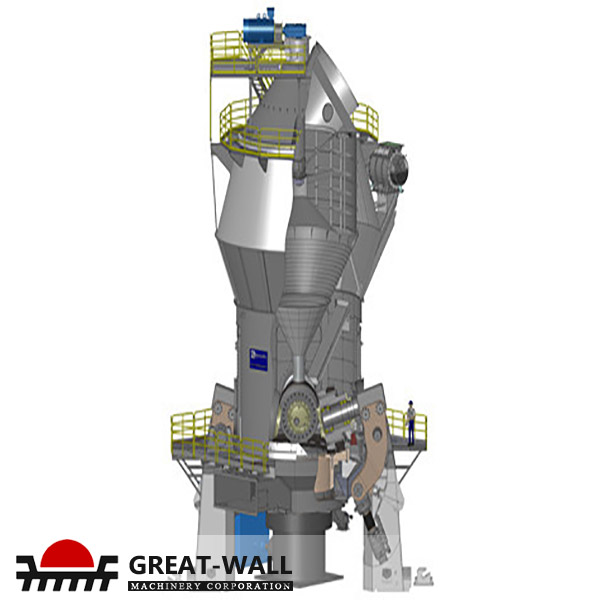

Appliaction of Coal Vertical Roller Mill

Vertical Roller mill is typically designed to process materials in medium hardness, like soft coal or bituminous coal, and it is mainly used in positive pressure pulverizing system of soft coal. It is widely used in electricity field, metallurgy sector, building material industry, chemical industry, etc. It is an ideal device that integrates crushing, drying, grinding, and grading conveying all together.

Working Principle of Coal Vertical Roller Mill

The grinding process of the main Coal Vertical Roller Mill is that the transmission device drives the central shaft. The upper part of the shaft connects with the quincunx rack, on the frame is loaded with the roller assembly, and forms a swinging pivot. The central shaft revolves around the central rotation, at the same time it revolves around the grinding rings, and it self also rotates on account of the grinding effect. The shovel system, in the lower part of rollers, is loaded on the lower part of the quincunx rack. In the process of rotating of the shovel and the roller, the material will be fed gasket layer between the rollers and ring. The outside centrifugal force (compression force) produced in this process will grind the material into small powder till the required powder is obtained.

The Specifications of Coal Vertical Roller Mill

| Model | Grinding Diameter (mm) | Roller Diameter (mm) | Roller Number (n) | Motor (kW) | Output (t/h) |

|---|---|---|---|---|---|

| GRMC12.20 | 1200 | 900 | 2 | 110 | 5 |

| GRMC16.20 | 1600 | 1000 | 2 | 250 | 12 |

| GRMC18.20 | 1800 | 1120 | 2 | 330 | 18 |

| GRMC20.30 | 2000 | 1250 | 3 | 430 | 20 |

| GRMC22.30 | 2200 | 1400 | 3 | 590 | 30 |

| GRMC23.30 | 2300 | 1450 | 3 | 640 | 35 |

| GRMC26.30 | 2600 | 1600 | 3 | 810 | 44 |

| GRMC28.30 | 2800 | 1750 | 3 | 1000 | 55 |

| GRMC30.30 | 3000 | 1900 | 3 | 1250 | 65 |

| GRMC35.30 | 3500 | 1900 | 3 | 1400 | 70 |

ModelGrinding Diameter (mm)Roller Diameter (mm)Roller Number (n)Motor (kW)Output (t/h)

Note: Mill spectral pattern benchmark

1. Material medium friction HGI=55~60;

2. Material moisture max 10%

3. Finished product granularity 80mmR3%;

4. Finished product moisture 0.5~1.0%;

5. The concrete mill installed power and technology parameter will be adjusted appropriately basing on the actual material property and the requirements of owner.

Advantages of Our Coal Vertical Roller Mill

Environmental Friendly

With small vibration, low noise, and the overall sealing, the system works under negative pressure, so there is no dust going out. (It meets the requirements of the state environmental protection.)

High Drying Ability

As the hot air inside contacts directly with the material, drying ability is higher, and it saves energy. By regulating the air temperature, it can meet requirements with different humidity.

Simple and Reliable Operation

Firstly, it is equipped with automatic control systems, so remote control makes it easy to operate. Second, it is equipped with one device, which prevents the roller from contacting with the liner directly, and avoids the destructive impact and severe vibration.

Company information

Xinxiang Great Wall Machinery Corporation’ s large foundry base, main plant building area covers 25000 m² with annual production volume of 50000 ton, and the weight of single product can reach 120 ton, enjoys advanced technology and equipments, and is the largest steel-casting base in the north of Henan Province, PRC.