Industry Knowledge

Energy-Efficient Cement Ball Mill Supplier Machine

Introduce of Energy-Efficient Cement Ball Mill Supplier Machine

Energy-Efficient Cement Ball Mill Supplier Machine has a strong adaptability of materials to production,broken rate large,easy to speed grinding fineness of the product and so on. Cement Ball Mill Supplier Machine has a strong adaptability of materials to production,broken rate large,easy to speed grinding fineness of the product and so on. Energy-Efficient Cement Ball Mill Supplier Machine is capable of dry production can also be wet,you can simultaneously grinding and drying operations.

Energy-Efficient Cement Ball Mill Supplier Machine is mainly used in grinding of cement finished products and materials,also to the metallurgical,chemical,electricity and other industrial and mining enterprises and other grinding various ore materials Grindability.Grinding can be used to open streams,but also to the composition and the separator flow grinding circle.Cement mill has a strong adaptability of materials to production,broken rate large,easy to speed grinding fineness of the product and so on. Energy-Efficient Cement Ball Mill Supplier Machine is capable of dry production can also be wet,you can simultaneously grinding and drying operations.

The structure of Energy-Efficient Cement Ball Mill Supplier Machine

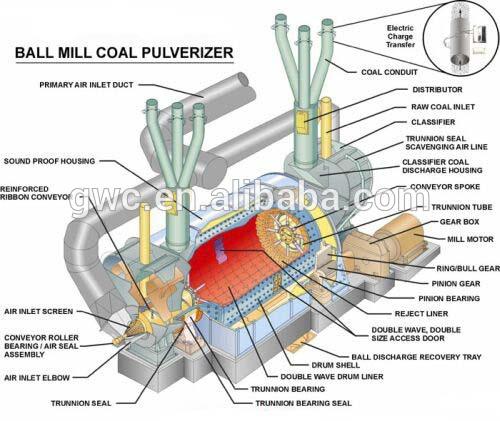

Energy-Efficient Cement Ball Mill Supplier Machine mainly consists of feeding part, discharging part, gyre part, transmission part (decelerated machine, small transmission gear, motor, electric control) and so on. The hollow axis adopts cast steel, the lining plate can be replaced, the big gyre gear is made of forging rolling gear, and there is lining plate in the cylinder body, which has favorable abrasion resistance. The ball mill has the features of stable running and reliable working.

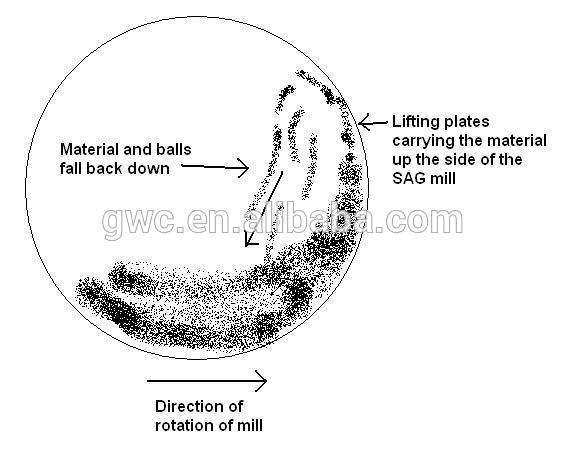

Energy-Efficient Cement Ball Mill Supplier Machine is a principle and cylindrical revolving device, and belongs to external gear-driving ball mill. The materials are transported by feeder, and gets into mill chamber through hollow screw axis equably, and there is lining plate and steel balls in the chamber. When the cylinder body goes round and round, the steel ball is taken to certain height, then falls down, and the materials are struck and grinded heavily. The above action repeats constantly till the size of materials reaches the required fineness. The powdery materials are discharged through discharge grate plate, and the milling work is over.

Working principle of Energy-Efficient Cement Ball Mill Supplier Machine

Energy-Efficient Cement Ball Mill Supplier Machine is a horizontal rotating device transmitted by the outer gear. The materials are transferred to the grinding chamber through the quill shaft uniformly. There are ladder liner and ripple liner and different specifications of steel balls in the chamber. The centrifugal force caused by rotation of barrel brings the steel balls to a certain height and impact and grind the materials.

Specifications of Energy-Efficient Cement Ball Mill Supplier Machine

| Model | Output (t/h) | Rotate Speed (r/min) | Feeding Granularity (mm) | Grinding Media Load (t) | Effective Volume (m³) | Motor (kW) | Weight (t) |

|---|---|---|---|---|---|---|---|

| Φ2.4×13 | 21-23 | 20.3 | ≤25 | 65 | 51.7 | 800 | 116 |

| Φ2.6×13 | 28-32 | 19.61 | ≤25 | 75 | 60 | 800 | 149 |

| Φ3.0×13 | 33-37 | 18.08 | ≤25 | 108 | 80.9 | 1250 | 172.3 |

| Φ3.2×13 | 45-50 | 17.8 | ≤25 | 128 | 92.4 | 1600 | 218 |

| Φ3.2×14 | 48-52 | 18.04 | ≤25 | 138 | 99.8 | 1800 | 228 |

| Φ3.5×13 | 55-60 | 17.09 | ≤25 | 160 | 111.2 | 2000 | 250 |

| Φ3.8×12 (closed-circuit) | 110 | 16.6 | ≤25 | 175 | 123.6 | 2500 | 203 (excluding drive parts) |

| Φ3.8×13 | 66 | 16.4 | ≤25 | 195 | 129.3 | 2500 | 286 |

| Φ4.0×13 | 80-85 | 15.5 | ≤25 | 235 | 155 | 2800 | 220 (excluding drive parts) |

| Φ4.2×13 (closed-circuit) | 140-155 | 15.6 | ≤25 | 240 | 157 | 3550 | 287 (excluding drive parts) |