Industry Knowledge

Grinding Roller For Steel Casting Parts

Introduction of Grinding roller

Grinding roller for vertical mill

Weight: 20-120T

Applicable devices: vertical mills

Application: Cement building material,

Grinding roller is a core part of vertical mill.Xinxiang Great Wall Machinery Corporation supplies customized service according to customers’ requirements. Besides, Xinxiang Great Wall Machinery Corporation obtains good reputations on grinding roller casting, finish machining and bead welding servicez

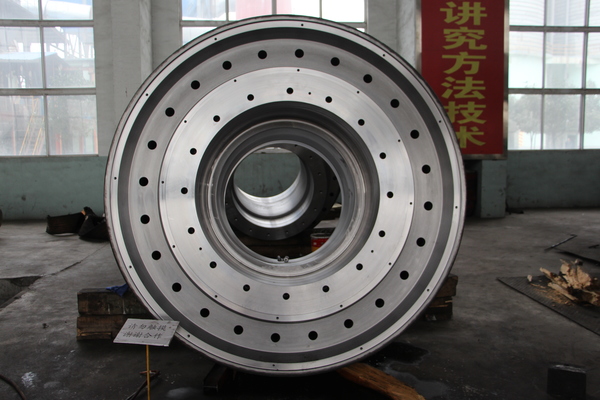

Picture of Grinding roller

Advantage of Grinding roller

1. High hardness, anti-cracking and wear resistant

2. Arc air gouging technology is applied by SHANGHAI SPECIAL METAL CO., LTD during finishing, making sure steel castings good appearance quality.

3. Xinxiang Great Wall Machinery Corporation promise: will do inspections before delivery to make sure each produced grinding roller is qualified, and refuse any inferior and defective products to be delivered.

Product processing

1. Wooden pattern Production

2. Molding

3. Pouring

4. First cleaning

5. Heat treatment – grinding (inspection)

6. Rough machining (inspection)-finishing machining (inspection)

7. Packing-delivering

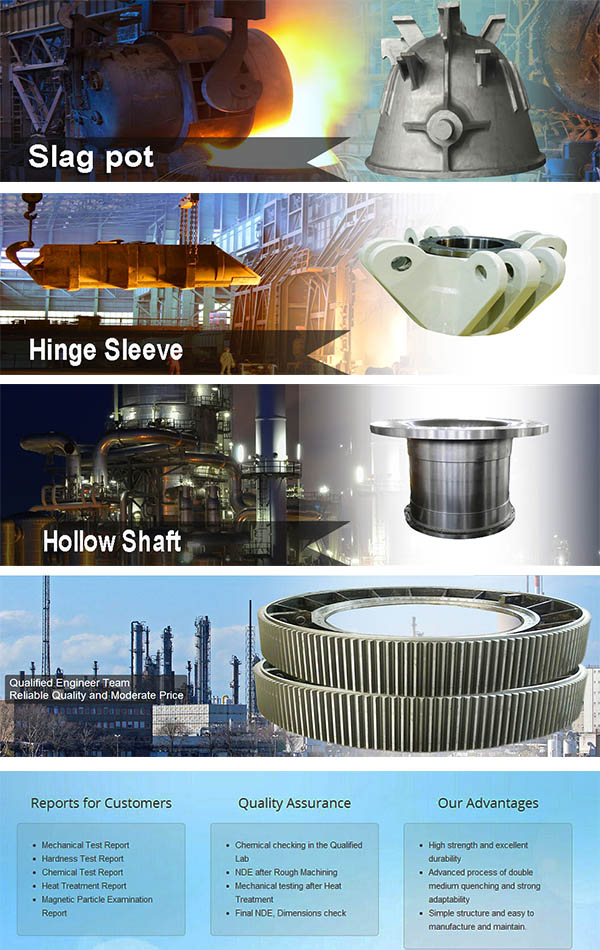

Quality assurance

The fabrication route is governed by the provisions of the implemented Quality System ISO 9001: 2000. The standard documentation ensures the full traceability of every process step:

• Manufacturer test certificates according to DIN EN 10.204 § 3.1 including chemical composition, mechanical properties and non-destructive examination;

• Dimensional check supported with a “as-built“ sketch;

• Record of the heat treatment chart

Our company and Factory

Xinxiang Great Wall Machienry Corporation is located at National Sustainable Development Experience Area, Mengzhuang Town, Huixian City, Henan Province. With beautiful environment, convenient transportation, it only takes one hour from Zhengzhou Xinzheng International Airport, and only 20 minutes from Xinxiang railway station. Bus 18 terminal stop can arrive at the company.

The main products are large steel casting under 120t per piece and steel ingot below 30t per piece, such as

Building materials machinery: ball mill hollow shaft, ring gear, sliding track, vertical mill grinding table, grinding roller, kiln supporting roller, kiln tyre.

Metallurgy, ceramics industry: rack, slag pot.

Shipbuilding parts, auto parts, cabinet housing, hammer, drill bits, etc.

FAQ

Do you provide after-sale service?

Yes. We have a professional after-sale service team to promptly and thoroughly solve your problems.

Do you provide equipment operation training?

Yes. We can send professional engineers to the working site for equipment installation, adjustment, and operation training. All of our engineers have passports.

How long is the warranty of your equipment? Do you supply spare parts?

Our warranty period is one year generally. We can supply spare parts.