Industry Knowledge

Turnkey project 500t/d Cement Production Line

500 TP cement plant cement plant include the steps of crushing, cement raw Material preparation and homogenization, pre-heating and decomposition, clinker calcination, cement grinding and cement packing. The design of 500 tpd new dry process cement production line contracted to build by Xinxiang Great Wall Machinery Co., Ltd adopts the dry process, which helps to reduce power consumption by 20% to 30% thus creating more profits for the user company.

Advantage of our 500 t/d Cement Plant

Most advanced production technology

The design of 500t/d new dry process cement production line contracted to build by Xinxiang Great Wall Machinery Co.,Ltd adopts the most advanced five-stage suspension preheater, RSP/F calciner and NSP rotary kiln. The large kiln hood increases the temperature of tertiary air effectively and makes the layout of tertiary air duct simple.

Turnkey Solution

Great Wall Machinery has an industry-leading technology team and in close collaboration with chief experts of vertical roller mill. Therefore, we can provide EP project according to the actual situation of the customer.

Timely Delivery

We have large-scale steel casting workshop and machining workshop, which ensures the equipment used in cement plant with high quality, and reduces project time.

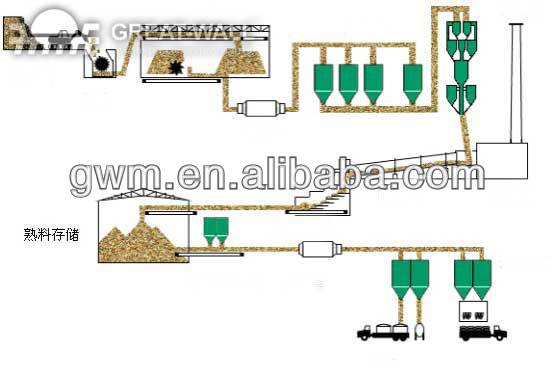

Working principle of our cement production line

1) limestone crushing

2) raw material storage and blending

3) raw meal grinding

4) raw meal homogenizing and kiln feeding

5) kiln inlet, kiln middle, kiln head and pulverized coal preparation

6) waste gas treatment at kiln inlet

7) clinker and admixture storage

8)cement grinding

9) cement storage and packing

Company Information

Xinxiang Great Wall Machienry Corporation, establelished in 1958, is one of the biggest Xinxiang Great Wall Casting Co., Ltd .cement making machine manufacture and supplier in Henan Province of China.Total area of the factory is 330000 m2, over 1100 employees including technicians.The annual processing capacity is over 80000 ton. Besides, we have a self-governed casting subsidiary, Xinxiang Great Wall Casting Co., Ltd, whose annual output is up to 50000 ton. That’s why we can supply you the best quality machinery with less lead time.

Technical Parameters

| No. | Equipment | Model | Quantity(set) | Amount |

|---|---|---|---|---|

| 1 | Limestone Crusher (Jaw Crusher) | 1 | ||

| 2 | Hammer Crusher | 1 | ||

| 3 | Raw Material Vertical Roller Mill | GRMR22.31 | 1 | |

| 4 | Coal Vertical Roller Mill | GRMC12.21 | 1 | |

| 5 | High Temperature Fan at Kiln Inlet | 1 | ||

| 6 | Electrostatic Precipitator at Kiln Inlet | 1 | ||

| 7 | Preheating and Precalcining System at Kiln Inlet | 1 | ||

| 8 | Rotary Kiln | φ3.0x45m | 1 | |

| 9 | Horizontal Pushing Grate Cooler | 1 | ||

| 10 | Cement Ball Mill | φ2.4x13m | 1 | |

| 11 | Packing Machine 4BBX(SG) Four Nozzles Fixed | 1 |

FAQ

1 how long is the product warranty period ?

A: the product warranty period is 12 months

2. I am a foreign customers, if the machine works wrong, how your company resolved ?

A: We have professional engineers abroad, after receiving your request, we will solve your problems at first time.

3. how much is MOQ of your machine?

A:our machines MOQ is 1 set and also support the mixed batch.

4.Where can we buy the machine's parts?

A: Our company can provide machines for your any time