Industry Knowledge

Introduction of Great Wall slag vertical mill

Introduction of our slag vertical mill:

Slag vertical mill can grind many materials such as clinker, slag, gypsum, fly ash or limestone to produce various cement types with various fineness. It combines drying, grinding and separation process into just one unit, making the footprint of the installation smaller and reducing the civil engineering costs, the cost of a vertical roller mill project is around 20 – 25% greater than a ball mill system of the same capacity.

Features of slag vertical mill:

1. The compound separator improved powder selection efficiency.

2. Has automatic function of roller uplifting and down falling can realize idling startup.

3. Adopt the sealing of jointing arc board, simple and reliable in structure with good sealing effect.

4. Resorting to the roller turning equipment can conveniently turn the roller out of the mill for the overhauling.

5. Mechanical limiting structure can avoid the direct metal friction and collision between the roller and millstone, increasing the use security.

6. The operation pressure is low in hydraulic pressure system, decreasing the oil leaking failure and vibration of mill, which is conductive operation and management.

7. Roller bearing adopts the concentrated cycle lubricating of thin oil, guaranteeing the running of the bearing under the conditions of low temperature and pure grease and effectively prolonging longevity of bearing.

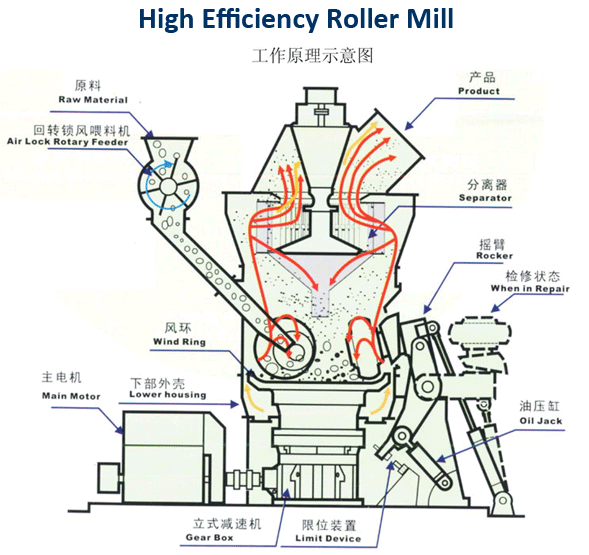

Work principle:

The materials drop to the center of the grinding table through the feed tube, and the grinding table, which is rotating at constant speed, scatters evenly the material to the outside by means of centrifugal force, making it form material bed with certain thickness. Meanwhile, the material is rolled and smashed by multiple rollers. The material gradually move to the fringe of the grinding table under the continuous of fringe force, when the leaving material meets the hot gas enter into mill through the vane and moves upward, entering the separator through the central casing of the mill, the material and the gas achieve sufficient exchange and moisture is evaporated quickly in the process. Powder concentrator controls the granularity of finished product at exit of roller mill, granules that are larger than regulated size are separated and fall to the grinding table, while those materials satisfying the fineness requirement enter the finished product storehouse through the powder concentrator.

technical parameters:

Specification | Diameter of Millstone D | Median Diameter of Roller d | Quantity of Roller n |

Standard Installed Power P |

Standard Ability Q |

mm | mm | n | kw | t/h | |

GRMS33.31 | 3200 | 1700 | 3 | 1600 | 50 |

GRMS35.41 | 3500 | 1800 | 4 | 1800 | 60 |

GRMS40.41 | 4000 | 1900 | 4 | 2240 | 70 |

GRMS43.41 | 4300 | 2120 | 4 | 2800 | 90 |

GRMS46.41 | 4600 | 2240 | 4 | 3150 | 105 |

GRMS48.41 | 4800 | 2240 | 4 | 3550 | 125 |

GRMS50.41 | 5000 | 2360 | 4 | 3800 | 140 |

GRMS53.41 | 5300 | 2500 | 4 | 4200 | 160 |

GRMS56.41 | 5600 | 2500 | 6 | 5000 | 180 |

About us:

Xinxiang Great Wall Machinery Co., Ltd was built in 1958. Covering an area of 330,000 square meter and having more than 1,100 employees, the company has a total asset of RMB 450 million and has passed through ISO9001:2008 quality management system certification, possessing the experience of equipment manufacturing for more than half a century, has formed the perfect operation and management system in design and development, product manufacturing, market promotion, equipment installation and after sales service.