Industry Knowledge

Vertical Roller grinding Mill with competitive price

Description:

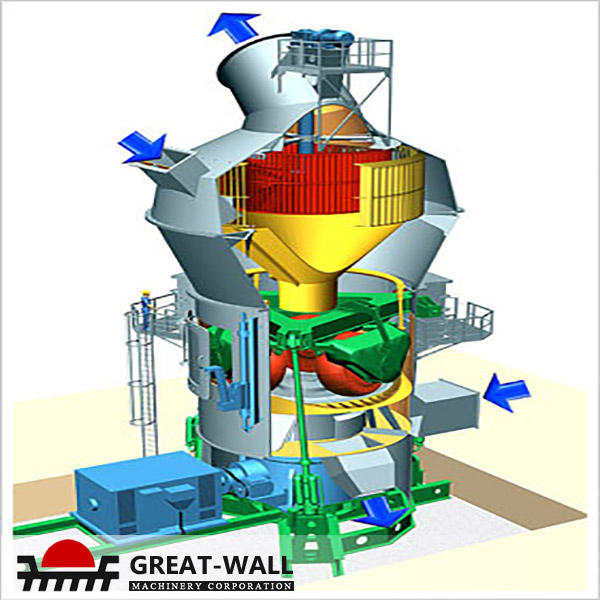

GGBS Vertical Roller grinding Mill with competitive price is an advanced grinding machine, which is developed on the basis of home & abroad high technology and production experience combination of various mills. vertical roller mill in cement industry price is an ideal device that integrates crushing, drying, grinding, and grading conveying all together.

Application:

GGBS Vertical Roller grinding Mill with competitive price is the equipment specializing in producing fine and superfine powder of non-inflammable, non-explosive and brittle materials with Moh's hardness under six, such as calcite, chalk, limestone, dolomite, kaolin, bentonite, talc, mica, magnesite, illite, pyrophyllite and vermiculite, sepiolite, attapulgite, rectorite, diatomite, barite, gypsum, alunite, graphite, fluorite, rock phosphate, Kalium ore, pumice, etc., totally more than 100 kinds of materials.

Work Principle:

Material through the feed tube fell on the center of vertical roller mill in cement industry price grinding plate, centrifugal force generated from the rotation of grinding plate uniformly scatters and flattens the materials outwards the surrounding area of vertical roller mill in cement industry price grinding plate, to forms a certain thick layer of materials bed, the material was crushed by number of rollers at the same time. Driven by the continuous centrifugal force to keep the materials moving to the outer edge of the grinding plate, the materials off the grinding plate rising with the hot air which enter from wind ring into the vertical roller mill, through the vertical roller mill in cement industry price shell into the middle of the separator, in this course materials and hot gas do a fully heat exchange, and the water quickly evaporates. Separator controls the output size of finished product, greater than the specified size are separated and fall back to the plate, while meet the fineness requirements are brought through the separator into the finished product warehouse.

Specifications:

| Model | Grinding Table Diameter (mm) | Roller Diameter (mm) | Roller Number (n) | Motor (kW) | Output (t/h) |

|---|---|---|---|---|---|

| GRMS33.31 | 3300 | 1700 | 3 | 1600 | 50 |

| GRMS35.31 | 3500 | 1800 | 3 | 1800 | 60 |

| GRMS40.41 | 4000 | 1900 | 4 | 2240 | 70 |

| GRMS43.41 | 4300 | 2120 | 4 | 2800 | 90 |

| GRMS46.41 | 4600 | 2240 | 4 | 3150 | 105 |

| GRMS48.41 | 4800 | 2240 | 4 | 3550 | 125 |

| GRMS50.41 | 5000 | 2360 | 4 | 3800 | 140 |

| GRMS53.41 | 5300 | 2500 | 4 | 4200 | 160 |

| GRMS56.61 | 5600 | 2500 | 6 | 5000 | 180 |

Company information:

Our service:

1.Pre-sales Service

Offering comprehensive technical and business consultation services;

Proposing th e most suitable scheme and equipment for our clients;

Designing and fabricating targeted products according to the special requirements of clients;

Training periodically high qualified service technician.

2.After-sales Service

Highly inspecting equipments in every working procedure, quality comes first;

Fast & Safe Delivery;

Assisting our clients for foundation construction of equipments;

Dispatching engineers to install and debug equipments;

Training the first-line operators on site;

Regularly visit clients to solve production problems;

Providing life-long maintenance service;

Providing technical exchanging;