Industry Knowledge

Coal Ball Mill Machine

(ISO 9001 & CE) Coal Ball Mill Machine

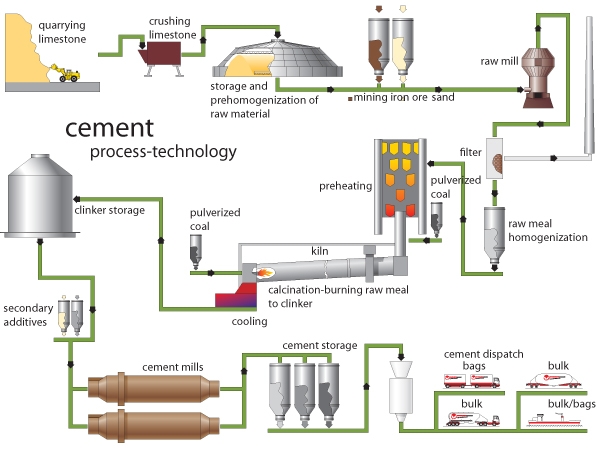

Coal mill is the equipment used for grinding and drying coal with different hardness. It is mainly composed of feeding device, principal axis, rotating part, transmission part, discharging part, high-pressure starting device and lubrication system. It also widely used to break various hardness of coal in cement industry, metallurgy industry and chemical industry and so on.

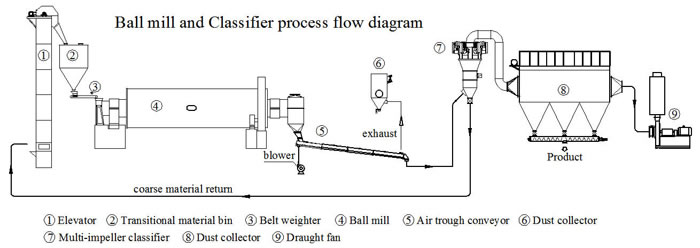

Working principle for coal Ball Mill

Coal Ball Mill Factory composed by feeding part, discharging part, turning part and driving part(reducer, small driving gear, electric motor and electric control). The quill shaft adopts cast steel part and the liner is detachable. The turning gearwheel adopts casting hobbing process and the drum is equiped with wear-resistant liner, which has good wear-resistance. Coal Ball Mill Factory is with stable and reliable working condition.

Moreover, according to different materials and discharging methods, there are dry coal ball mills and wet coal ball mills for your choice.

Data of coal ball mill

| Model (m) | Output (t/h) | Rotate Speed (r/min) | Grinding Media Load (t) | Effective Volume (m³) | Motor (kW) | Gearbox | Weight (t) |

|---|---|---|---|---|---|---|---|

| Φ2.4×4.75 | 12 | 20.4 | 22 | 19.3 | 280 | ZD60 | 50 |

| Φ2.4×4.5+2.0 | 12 | 20.4 | 22.6 | 18.3 | 280 | JD450 | 70.1 |

| Φ2.8×5.75+2.25 | 18-20 | 18.7 | 38 | 32.9 | 500 | MBY630 | 116.5 |

| Φ2.9×4.1 | 16 | 18.8 | 35 | 27.1 | 475 | JDX560 | 74 |

| Φ3.0×6.5+2.5 | 20 | 18.4 | 46.5 | 43.3 | 710 | JDX630 | 119 |

| Φ3.2×6.5+2.5 | 28 | 18 | 65 | 67 | 710 | JDX800 MBY800 | 153 |

| Φ3.4×6.0+3.0 | 30 | 17.47 | 60 | 64 | 900 | JDX800 | 167 |

| Φ3.4×7.5+1.5 | 30-38 | 17.5 | 70 | 64.1 | 800 | JDX710 | 160 |

| Φ3.6×6.5+2.5 | 32 | 17 | 60 | 69 | 1000 | MBY800 | 203 |

| Φ3.8×70+2.5 | 38 | 16.4 | 80 | 75 | 1250 | MBY710 | 216 |

The feature of coal Ball Mill

1.It is an efficient tool for grinding coal into fine powder.

2.The capacity and fineness can be adjusted by adjusting the diameter of the ball.

3.Low speed driving unit with lifting device, convenient for maintenance.

4.New endurable wearing parts to increase service life of vulnerable parts.

5.Stable performance and easy installation.

Company Information

Xinxiang Great Wall Machienry Corporation, establelished in 1958, is one of the biggest Xinxiang Great Wall Casting Co., Ltd .cement making machine manufacture and supplier in Henan Province of China.Total area of the factory is 330000 m2, over 1100 employees including technicians.The annual processing capacity is over 80000 ton. Besides, we have a self-governed casting subsidiary, Xinxiang Great Wall Casting Co., Ltd, whose annual output is up to 50000 ton. That’s why we can supply you the best quality machinery with less lead time.

Our Services

1.Pre-sales Service

Offering comprehensive technical and business consultation services;

Proposing th e most suitable scheme and equipment for our clients;

Designing and fabricating targeted products according to the special requirements of clients;

Training periodically high qualified service technician.

2.After-sales Service

Highly inspecting equipments in every working procedure, quality comes first;

Fast & Safe Delivery;

Assisting our clients for foundation construction of equipments;

Dispatching engineers to install and debug equipments;

Training the first-line operators on site;

Regularly visit clients to solve production problems;

Providing life-long maintenance service;

Providing technical exchanging;

our customer

FAQ

1 how long is the product warranty period ?

A: the product warranty period is 12 months

2. I am a foreign customers, if the machine works wrong, how your company resolved ?

A: We have professional engineers abroad, after receiving your request, we will solve your problems at first time.

3. how much is MOQ of your machine?

A:our machines MOQ is 1 set and also support the mixed batch.

4.Where can we buy the machine's parts?

A: Our company can provide machines for your any time

Contact us