Industry Knowledge

Great-wall cement ball mill

Introduction of cement ball mill

Cement ball mill are often used in the cement production line to make the steel slag into granulated blast-furnace slag powder, which is usually used in concrete in combination with Portland cement as part of blended cement. It is widely used in the cement industry, Iron and Steel industry.

Application of cement ball mill

Cement ball mill is generally used to grind material 1/4 inch and finer, down to the particle size of 20 to 75 microns. To achieve a reasonable efficiency with ball mills, they must be operated in a closed system, with oversize material continuously being recirculated back into the mill to be reduced. Various classifiers, such as screens, spiral classifiers, cyclones and air classifiers are used for classifying the discharge from ball mills. Ball mill is an efficient tool for grinding many materials into fine powder. The ball mill is used to grind many kinds of mine and other materials, or to select the mine. It is widely used in building material, chemical industry, etc. There are two ways of grinding: the dry process and the wet process. It can be divided into tabular type and flowing type according to different forms of discharging material.

Features of cement ball mill

1. Less investment, more energy-saving than similar products.

2. easy to operate, safe to use, stable and reliable performance.

3. Final Product Fineness: 3800-4000cm2/g.

4.Cost recovering on Investment is soon (1-3 years)and profitable.

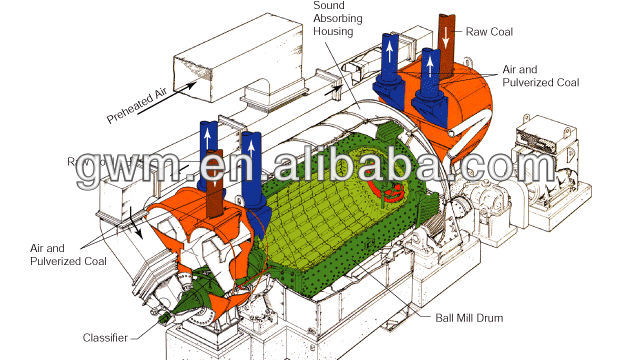

Working principle of cement ball mill

Cement ball mill is a skeleton pattern ball mill with horizontal cylindrical turning gear, drive by outer gear and two hoppers. The material goes to the first hopper after the spiraling by the quill shaft from the feeding equipment. The hopper has ladder sheathing or corrugated sheathing with steel balls inside, which will fall under the effect of centrifugal force by barrel turning to ram hard and grind material. After the kibbling in the first hopper, by monolayer partition panel, the material will enter the second hopper, which has plane scale board with steel ball inside to grind material. The powder material will be discharged from the grid plate to finish the grinding.

Structures of cement ball mill

Cement ball miller is composed by feeding, discharging, rotary part, transmission part (reducer, small transmission gear, motor, electric control) and other major parts. Hollow shaft adopts steel, lined with removable, rotary wheel adopts gear hobbing machining, casting cylinder body with wear resistant lining board, main bearing adopts double-row self-aligning spherical roller bearing, which can reduce cement consumption by 30%. It can also be used to an open-circuit grinding system or a closed-circuit grinding system.

Cement ball mill specifications

Model | Cylinder Diameter (mm) | Cylinder Length (mm) | Effective Volume (m3) | Mill Rotate Speed (r/min) | Grinding Media Weight (t) | Drive Mode | Power(kW) | Rotate Speed (r/min) | Weigth (t) |

MQY15×30 | 1500 | 3000 | 5 | 26.6 | 9 | Edge | 95 | 742 | 18.5 |

MQY15×36 | 1500 | 3600 | 5.7 | 26.6 | 10.6 | Edge | 95 | 742 | 17.22 |

MQY21×30 | 2100 | 3000 | 9.4 | 22 | 15 | Edge | 200 | 740 | 45 |

MQY24×30 | 2400 | 3000 | 12.2 | 21 | 22.5 | Edge | 250 | 980 | 55 |

MQY24×60 | 2400 | 6000 | 22.8 | 20.7 | 43 | Edge | 400 | 740 | 65 |

MQY27×36 | 2700 | 3600 | 18.5 | 20.5 | 39 | Edge | 400 | 187.5 | 61.34 |

MQY27×45 | 2700 | 4500 | 23.5 | 20.5 | 43.5 | Edge | 500 | 187.5 | 76 |

MQY28×80 | 2800 | 8000 | 43 | 20 | 78.6 | Edge | 800 | 137 | 115 |

MQY32×36 | 3200 | 3600 | 26.3 | 18.3 | 48.4 | Edge | 500 | 167 | 116.94 |

MQY32×45 | 3200 | 4500 | 32.9 | 18.3 | 60.5 | Edge | 630 | 167 | 124.23 |

MQY32×75 | 3200 | 7500 | 55.5 | 18.3 | 102 | Edge | 1250 | 734 | 154 |

MQY34×45 | 3400 | 4500 | 37 | 18.4 | 74.6 | Edge | 800 | 167 | 129.8 |

MQY34×56 | 3400 | 5600 | 45.8 | 17.9 | 84.3 | Edge | 1120 | 985 | |

MQY36×50 | 3600 | 5000 | 46.7 | 17.5 | 85.96 | Edge | 1250 | 167 | 150 |

MQY36×60 | 3600 | 6000 | 54 | 17.3 | 102 | Edge | 1250 | 167 | 162.7 |

MQY36×85 | 3600 | 8500 | 79 | 17.4 | 131 | Edge | 1800 | 742 | 235 |

MQY36×90 | 3600 | 9000 | 83.5 | 17.4 | 138 | Center | 1800 | 743 | 286 |

MQY40×60 | 4000 | 6000 | 69.8 | 16 | 126 | Edge | 1500 | 200 | 203.5 |

MQY40×135 | 4000 | 13500 | 155 | 16 | 233 | Edge | 3300 | 200 | 343 |

MQY43×61 | 4270 | 6100 | 80 | 15.67 | 144 | Edge | 1750 | 200 | 215.3 |

MQY50×64 | 5030 | 6408 | 120 | 14.4 | 251 | Edge | 2600 | 200 | 318.5 |

MQY55×65 | 5500 | 6500 | 143.3 | 13.8 | 264 | Edge | 3400 | 200 | 451.5 |

MQY55×85 | 5500 | 8500 | 187.4 | 13.8 | 335 | Edge | 4500 | 200 | 451.5 |