Industry Knowledge

Great-wall rotary kiln for Lime

Introduction of lime rotary kiln

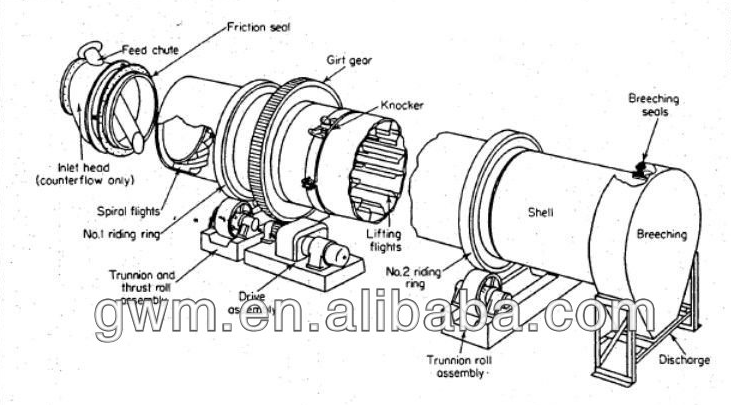

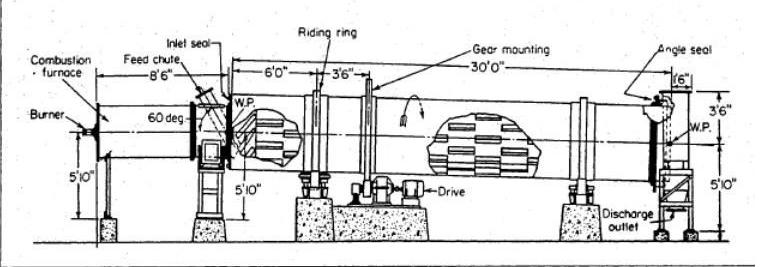

Lime rotary kiln is the main equipment of lime production line. It is widely used for many industries like metallurgy, chemical industry, building refractory materials, environmental protection, etc. The rotary kiln consists of cylindrical shell, supporting device, supporting device of thrust roller, driving unit, moveable kiln head, sealing device on the tail of kiln, coal dust pipe device, etc., the kiln body has a certain tilt angle with level. The whole kiln body is supported by the roller supporting device, and it is also equipped with thrust roller device to control the up and down movement of the kiln body.

Characteristics of Our lime production plant

1. Supporting device: advanced shaft structure, automatic temperature measuring device and electrical heating.

2. Catch wheel: including two kinds mechanical wheel and hydraulic pressure

3. Gears: single or double. Control the rotating speed by buncher, DE machine and frequency variable motor. Be reliable, energy-saving, and efficient.

4. Cylinder type bolster: lower bolster has three types: fixed, zoom and floating. The structure is simple, replacement is convenient and won’t hurt cylinder.

5. Sealing equipment: there are many kinds for choice according to kiln models, including air cylinder edge sealing, spring edge sealing, and graphite block sealing and combination for above. The sealing effect is very good.

6. Kiln head hood: including stationary type and flexible type.

Working principle of lime production plant

Structure of rotary kiln

The rotary kiln is made of drum, support bearing, hydraulic thrust device, transmission, movable kiln head, kiln end seal, and pulverized coal injection device. The kiln body is slightly inclined to the horizontal, and is supported by hydraulic thrust roller and roller bearing.

To ensure proper functioning of the kiln even when the main power supply is cut off, we add auxiliary drive to the kiln that prevents kiln deformation. Advanced technologies ensure reliable seal at both lower and upper ends of the kiln.

Rotary kiln specifications

Model | Output (t/d) | Main Drive (r/min) | Motor (kW) | Regulating Range (r/min) | Gearbox Velocity Ratio | Weight (t) |

Φ2.2×50 | 96 | 0.125-1.25 | 30 | 132-1320 | 157 | 130.71 |

| Φ2.5×50 | 130 | 0.516-1.549 | 55 | 440-1320 | 99.96 | 167.5 |

| Φ3×48 | 850 | 0.3309-3.309 | 90 | 100-1000 | 32.11 | 237 |

| Φ3.2×48 | 1000 | 0.375-3.75 | 160 | 100-1000 | 27.469 | 252 |

| Φ3.2×50 | 1200 | 0.398-3.975 | 190 | 150-1500 | 40.85 | 263 |

| Φ3.3×52 | 1200 | 0.391-3.91 | 190 | 100-1000 | 27.707 | 280.8 |

| Φ4×60 | 2500 | 0.396-3.96 | 315 | 100-1000 | 34.601 | 487.5 |

| Φ4.2×60 | 2800 | 0.4165-4.165 | 420 | 100-1000 | 35.526 | 576.1 |

| Φ4.3×62 | 3000 | 0.398-3.98 | 420 | 100-1000 | 35.714 | 598.5 |

| Φ4.3×64 | 3200 | 0.449~4.49 | 450 | 100~1000 | 24.365 | 585 |

| Φ4.5×66 | 4000 | 0.41~4.1 | 630 | 100~1000 | 34.069 | 710.4 |

| Φ4.8×70 | 5000~5500 | 0.4~4.0 | 630 | 100-1000 | 30.876 | 845.3 |

| Φ4.8×72 | 5000 | 0.403~4.03 | 560 | 100~1000 | 30.365 | 847 |

| Φ4.8×74 | 5000 | 0.35~4 | 630 | 130~1500 | 42.226 | 841 |